Driven by the continuous upsurge in global infrastructure investment and the accelerated advancement of construction industrialization,

CNC stirrup

bending machines—core equipment in the

steel bar processing sector—are undergoing a new round of industrial upgrading centered on intelligence, efficiency, and green technology. Statistics indicate that the global market size for steel bar processing machinery exceeded USD 21.5 billion in 2025, with CNC stirrup bending machines emerging as a major growth driver, posting a compound annual growth rate of 6.8%. Chinese manufacturers, backed by over a decade of technical accumulation and one‑stop service capabilities, now occupy a significant position in the global market.

![Stirrup Bending Machine Stirrup Bending Machine]()

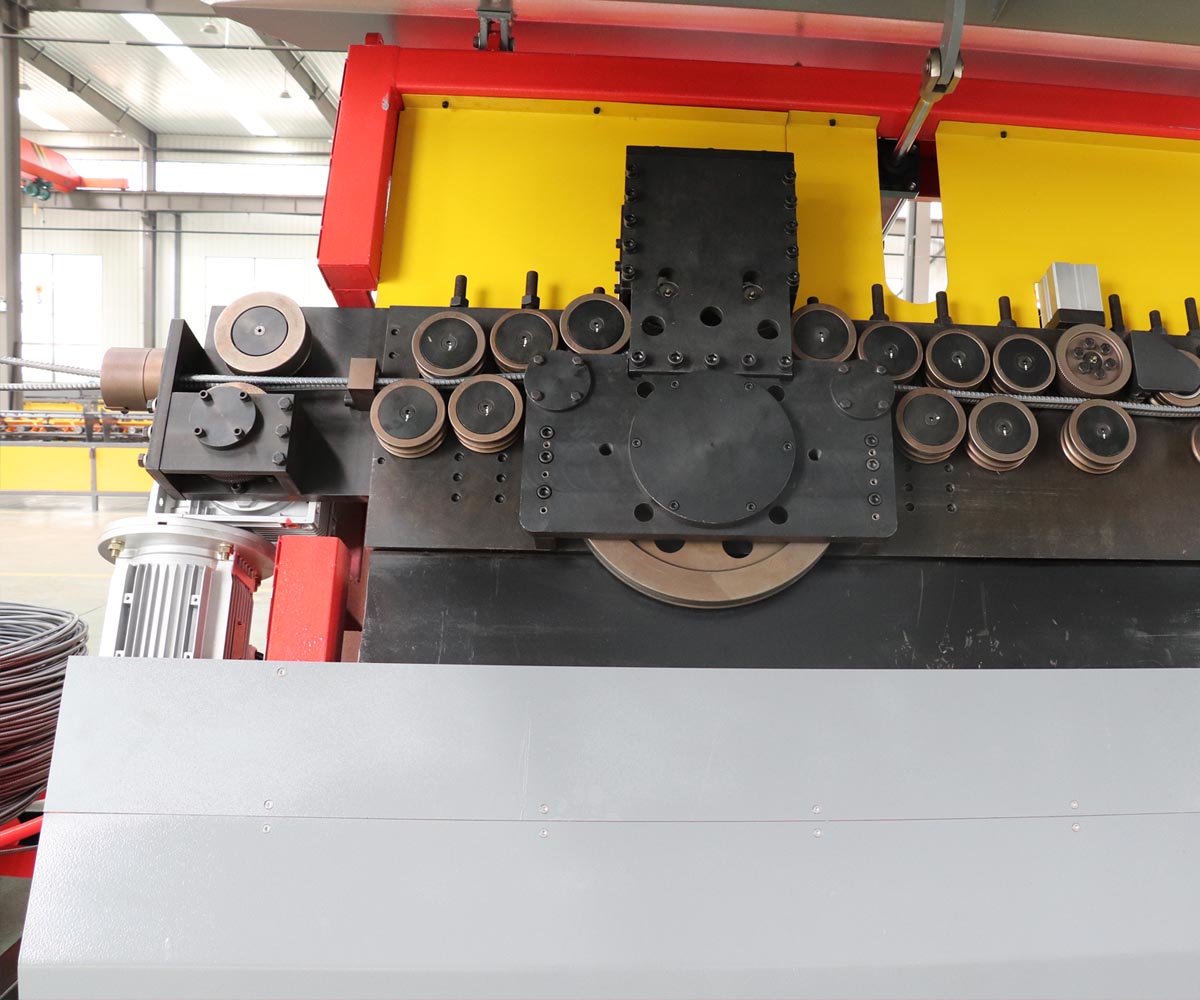

As a professional manufacturer with ten years of deep engagement in the industry, we have witnessed and participated in the technological evolution of CNC stirrup bending machines. Today’s equipment has completely broken away from the limitations of traditional manual processing, realizing full‑process automation from feeding, straightening, and bending to cutting. Equipped with a 10.5‑inch high‑definition touch screen and an intelligent control system, operators no longer require specialized programming skills—simply inputting parameters allows one‑click production start‑up. Even ordinary workers can become proficient after short‑term training, effectively addressing the labor shortage challenge in the construction industry. The built‑in library of 500 processing patterns covers rectangular, circular, and special‑shaped stirrups, and supports storage of hundreds of workpiece recipes, enabling rapid switching between multiple specifications and fully meeting the diverse processing needs of modern infrastructure projects.

Dual breakthroughs in precision and efficiency have become the core competitiveness of modern CNC stirrup bending machines. Adopting high‑precision servo motors and a full‑closed‑loop numerical control system, these machines achieve a bending angle accuracy of ±0.5° and a length error within ±1 mm, while the straightness of straightened steel bars is controlled within ±1.5 mm per meter. This ensures the standardized production of reinforcement components and fundamentally enhances the stability of concrete structures. In terms of productivity, single‑bar models can process 12–15 standard stirrups per minute, and advanced double‑bar models can reach up to 2,100 pieces per hour, with a daily processing capacity exceeding 15 tons—equivalent to the output of 20–30 skilled workers and 8–10 times the efficiency of traditional manual processing—greatly shortening construction schedules.

Green energy conservation, safety, and durability have set new industry benchmarks. In response to green trade barriers such as the EU’s Carbon Border Adjustment Mechanism (CBAM), the new generation of CNC stirrup bending machines has reduced energy consumption by 28% compared with traditional models through technological innovation. Low‑noise design and scrap‑optimization algorithms further align with eco‑friendly construction requirements. The machine body is formed by one‑piece welding of thickened steel plates, and core components are made of high‑strength alloy steel treated with special processes, ensuring a service life of 8–10 years and suitability for long‑term, heavy‑load operation. Meanwhile, the equipment is equipped with multiple safety features such as emergency braking and overload protection, as well as an intelligent fault diagnosis system, providing comprehensive protection for operators.

![Stirrup Bending Machine Stirrup Bending Machine]()

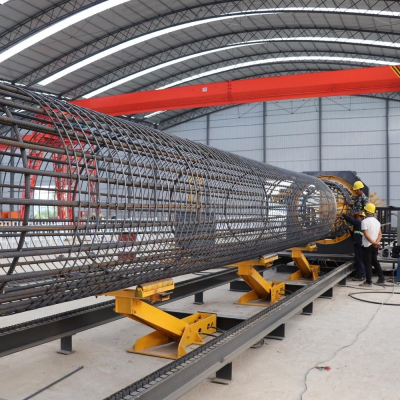

In terms of market layout, leveraging opportunities presented by the “Belt and Road” Initiative and RCEP regional cooperation, domestically produced CNC stirrup bending machines have been exported to India, Vietnam, Africa, and other countries and regions, playing an important role in landmark projects such as the Jakarta‑Bandung High‑Speed Railway and the East Coast Rail Link in Malaysia. We offer not only CNC stirrup bending machines but also one‑stop intelligent solutions covering

steel cage welding machines, hydraulic steel bar shear lines, and other core equipment, accompanying customers through every stage of project construction—from product customization and technical support to after‑sales service.

As construction industrialization continues to rise and intelligent transformation deepens, CNC stirrup bending machines are evolving toward IoT integration, remote operation and maintenance, and digital twins. In the future, we will continue to uphold the principle of “quality first, innovation‑driven”, deepen R&D in core technologies, and further improve equipment automation and IoT penetration. We are committed to providing more precise, efficient, and environmentally friendly steel bar processing solutions for global infrastructure projects, helping the industry achieve sustainable development.