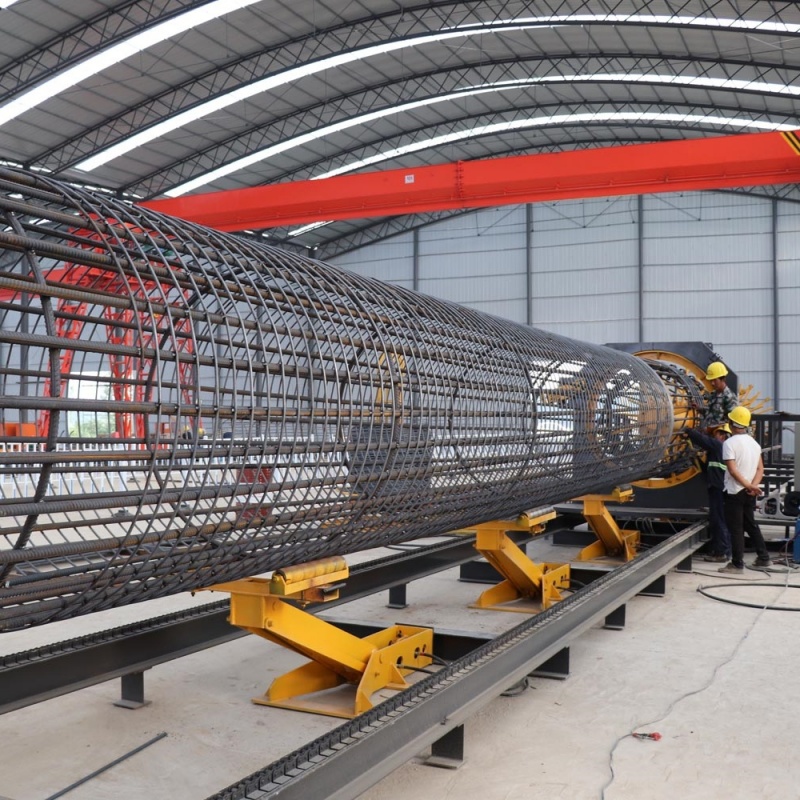

As a core equipment for the intelligent transformation of the infrastructure industry, the steel cage roller welding machine is tailor-made for steel cage processing in projects such as bridge pile foundations, high-speed rail foundations, and municipal utility tunnels. It realizes the full-process automation of main reinforcement positioning, stirrup winding, and automatic welding through an industrial-grade PLC numerical control system, completely replacing the traditional manual binding and welding mode. It solves the industry pain points of low efficiency, large quality fluctuations, and consumable waste in manual processing. Currently, it has been applied on a large scale in key projects such as the Shiyan-Tianshui Expressway and Lianyungang-Suzhou Expressway of China Railway 15th Bureau, and has become a standard equipment in intelligent steel bar processing plants.

![steel cage roller welding machine steel cage roller welding machine]()

Core Configuration: Modular Structure Ensures Stable Operation

The equipment adopts a modular design of "intelligent control + precise execution + efficient welding", and each unit operates synergistically to realize full closed-loop control of processing. The key configuration highlights are as follows:

Intelligent Numerical Control System: Equipped with an industrial-grade PLC controller and a 10-inch high-definition touch screen, it has built-in 50+ sets of standardized processing parameter templates. It supports one-click setting of key parameters such as steel cage diameter, length, and main reinforcement spacing. New operators can take up their posts after 1 hour of training. Some high-end models are compatible with the BIM-MES system, which can upload processing data in real time to realize visual management of project progress.

Automatic Feeding and Welding Unit: Equipped with a vibrating bed type main reinforcement silo and a servo feeding mechanism, it realizes automatic sorting and feeding of main reinforcements with Φ12-40mm. The stirrup adopts a continuous feeding mode of coiled round steel, and is welded synchronously with 3-6 CO₂ shielded welding torches. The weld spot firmness is 40% higher than that of manual welding, and the single-point welding time is only 0.8 seconds.

Precise Positioning Mechanism: The fixed rotating disc and moving rotating disc are forged integrally with quenched and tempered steel, and the tolerance of the main reinforcement positioning hole is controlled within ±0.5mm. The moving disc is driven by a servo motor, and the walking accuracy reaches ±1mm, which ensures the uniformity of the stirrup spacing and effectively avoids the problems of "loosening and deviation" caused by manual winding.

Stable Support System: The machine body is formed by welding thickened steel plates, and the core load-bearing components are quenched. It can operate continuously for 24 hours without failure in complex construction site environments such as dust and vibration. Equipped with hydraulic support feet, no fixed foundation is required during installation, and a 4-person team can complete commissioning and put into production in 3 days.

Core Performance Advantages: More Competitive in Cost Reduction and Efficiency Enhancement

1. Doubled Efficiency: Direct 60% Reduction in Labor Costs

The traditional manual processing of a 12-meter-long steel cage requires 6-8 people to cooperate for 4 hours. However, the fully automatic steel

cage roller welding machine only needs 1 operator for monitoring. It can process 12-15 sections per single shift (8 hours), and the maximum daily output can reach 30 sections (two-shift system), with an efficiency increase of more than 300%. Data from the Shiyan-Tianshui Expressway project of China Railway 15th Bureau shows that after the equipment was put into use, the steel cage processing team was reduced from 12 people to 3 people, saving more than 600,000 yuan in labor costs annually.

2. Excellent Quality: "Zero Rework" in Supervision Sampling Inspection

Through the dual control of the numerical control system and mechanical positioning, the main reinforcement spacing error is ≤±2mm, the stirrup spacing accuracy is ±5mm, and the cage diameter consistency error is ≤±3mm, which is far higher than the requirements of the Code for Construction Quality Acceptance of Concrete Structure Engineering. The welding link adopts multi-welding head synchronous operation, the weld fullness reaches 99.5%, and there are no internal defects in ultrasonic flaw detection. The qualification rate is stably above 99.8%. After application in the Shiyan-Tianshui Expressway project, the supervision unit realized "exemption from inspection" for mechanically processed steel cages, and the on-site hoisting and docking efficiency increased by 35%.

3. Energy and Material Saving: 15% Reduction in Comprehensive Costs

The equipment is equipped with an intelligent nesting algorithm, which can optimize the main reinforcement blanking plan according to the processing list. Combined with the stirrup non-lap welding technology, the material utilization rate is increased by 1.5%-2%, and large-scale projects can save more than 15 tons of steel consumables annually. In terms of energy consumption, the intermediate frequency inverter welding power supply is adopted, which reduces energy consumption by 25% compared with traditional welding machines, and a single equipment can save more than 20,000 yuan in electricity bills annually.

4. Flexible Adaptability: Quick Switch Between Multiple Scenarios

The standard model supports the processing of cage diameters from Φ600-2500mm and cage lengths from 2-27m. It can adapt to main reinforcements of Φ12-40mm and stirrups of Φ6-16mm, and is compatible with various materials such as plain round steel and deformed steel. There is no need to replace the core mold when switching specifications; only parameter adjustment on the touch screen is required, and the transition from bridge pile foundation cage to municipal utility tunnel cage can be completed in 20 minutes. The modular design is convenient for trans-project transportation, and the disassembly and assembly cycle only takes 3-5 days.

Core Technical Parameters

| Parameter Item | Standard Model Index | High-end Customized Model Index |

|---|

| Processing Cage Diameter Range | Φ600-2000mm | Φ800-2500mm |

| Processing Cage Length Range | 2-18m | 2-27m |

| Main Reinforcement Specification | Φ12-32mm | Φ16-40mm |

| Single Section Processing Efficiency | 30-40 minutes/section (12m) | 20-30 minutes/section (12m) |

| Stirrup Spacing Accuracy | ±5mm | ±3mm |

| Total Power | 30-45kW | 45-60kW |

Application Scenarios and After-sales Service

The equipment is widely applicable to various infrastructure scenarios: bridge pile foundation steel cage processing (such as expressways, railway bridges), municipal engineering (subway stations, urban utility tunnels), housing construction foundation construction, large-scale production in prefabricated component factories, etc. According to the needs of different scenarios, customized solutions can be provided, such as ultra-long cage processing models and special-shaped cage welding modules.

The after-sales service system is complete: free on-site installation and commissioning, 3-person/2-day special training are provided; the whole machine has a 1-year warranty, and core components (PLC system, servo motor, welding torch) have a 2-year warranty; 24-hour technical hotline response, and 32 service outlets across the country realize on-site maintenance within 48 hours, ensuring the equipment operation rate ≥95%.