CNC Steel Cage Roller Welding Machine Emerges as Core Equipment in Infrastructure Intelligent Transformation

2025/12/04 14:38

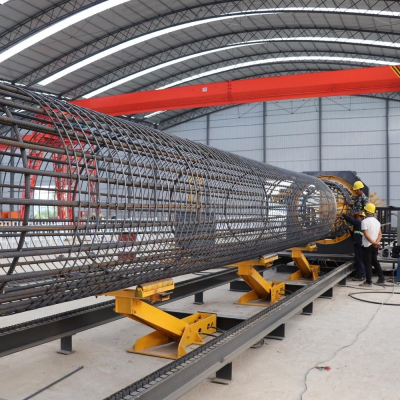

With the accelerated intelligent transformation in China's infrastructure sector, CNC steel cage roller welding machines are gradually replacing traditional manual processing methods and becoming core equipment for key projects such as bridges and high-speed railways. Reporters learned from the construction sites of multiple key projects including Huizhou-Zhaoqing Expressway and Weifang-Suzhou High-Speed Railway that the steel cage roller welding machines equipped with PLC intelligent control systems not only quadruple the processing efficiency but also achieve millimeter-level precision control, effectively solving the pain points of traditional processes such as unstable quality and difficult construction period guarantee.

At the intelligent steel cage manufacturing and distribution center of Huizhou-Zhaoqing Expressway, reporters saw three CNC steel cage roller welding machines operating at high speed, with processes including main reinforcement positioning, stirrup winding and automatic welding completed in one go. "Traditionally, processing a 12-meter-long steel cage manually required 5 workers and took 4 hours. Now, one equipment with one operator can finish it in 1 hour, and the welding qualification rate has increased from 85% (manual) to 99.8%," the person in charge of the center introduced. The fully automatic steel cage welding workstation configured in the project is linked with the CNC roller welding machine. By presetting multiple sets of specification parameters, production can be started with one click on the touch screen. The uniformity error of the spacing between stirrups and main reinforcements is controlled within ±2mm, completely solving the problems of "loosening and deviation" that are prone to occur in manual winding.

The personalized demands of large-scale projects for the length and diameter of steel cages are driving the continuous upgrading of equipment technology. The Weifang-Suzhou High-Speed Railway Project Department of China Railway Fourth Engineering Bureau adopted a customized CNC steel cage roller welding machine and successfully realized the one-time processing and forming of 17-meter-long pile foundation steel cages, saving 30% of the connection time compared with the traditional segmented welding process. The technical director of the project stated that the extended base design of the equipment combined with CO₂ shielded welding technology not only ensures the concentricity of large-sized steel cages but also controls the steel tension loss rate within 5%, fully meeting the high-strength requirements of high-speed railway pile foundations.

Policy guidance provides strong impetus for the popularization of equipment. In the elimination catalog released by Nanchang Housing and Urban-Rural Development Bureau in April 2025, traditional processes such as manual binding and segmented welding are clearly included in the restricted scope, and intelligent equipment such as steel cage roller welding machines are recommended as replacements. At the same time, the 2025 version of Guidelines for the Construction of Steel Bar Processing Plants requires that the proportion of intelligent processing equipment should not be less than 80%. The steel cage roller welding machine is compatible with the BIM-MES integrated platform, enabling closed-loop management of processing data and construction links, thus becoming an essential equipment to meet the standards.

Driven by both technological innovation and market demand, the steel cage roller welding machine industry has shown a rapid growth trend. According to the latest report from Global Market Insights, the global steel cage roller welding machine market size reached 394 million US dollars in 2024 and is expected to exceed 545 million US dollars by 2031, with a compound annual growth rate of 4.7% from 2025 to 2031. Domestic enterprises have made breakthroughs in core technology fields. The fifth-generation equipment developed by Zhongji Luyuan Machinery has introduced a machine vision positioning system, improving the processing precision to ±1mm, and has served many construction enterprises.

Industry analysts pointed out that with the implementation of the policy requiring the proportion of high-strength steel bars to reach 80%, the adaptability upgrade of steel cage roller welding machines will become the focus of competition. "At present, 32% of large-scale steel bar processing enterprises in China have completed the transformation of intelligent equipment. It is expected that the equipment penetration rate will increase from 35% to more than 60% in the next three years, driving the processing loss rate of the infrastructure industry down from the traditional 5% to less than 1.5%," the analyst said. The steel cage roller welding machine is transforming from a single processing equipment to an intelligent production unit, providing core support for the green and efficient development of the infrastructure industry.