Zhongji Luyuan Partners with China Railway 24th Bureau to Build Smart Rebar Processing Center for Zhang-Shan High-Speed Rail

The Zhangzhou–Shantou High-speed Railway (Zhang-Shan HSR), also known as the Zhang-Shan Section of the Ningbo–Guangzhou High-speed Railway, is a key component of China’s "Eight Vertical and Eight Horizontal" high-speed rail network. Spanning approximately 175 kilometers, the line connects Zhangzhou in Fujian Province with Shantou in Guangdong Province, with a design speed of 350 km/h and 7 stations along the route.

Construction of the Zhang-Shan HSR officially began on February 4, 2024, marking a vital step in building the southeast coastal passenger transport corridor between Guangzhou, Shantou, Zhangzhou, Xiamen, and Fuzhou. Once completed, this project will significantly enhance connectivity between the Guangdong-Hong Kong-Macao Greater Bay Area and the Haixi Economic Zone, promoting economic collaboration between southern Fujian and the Pearl River Delta.

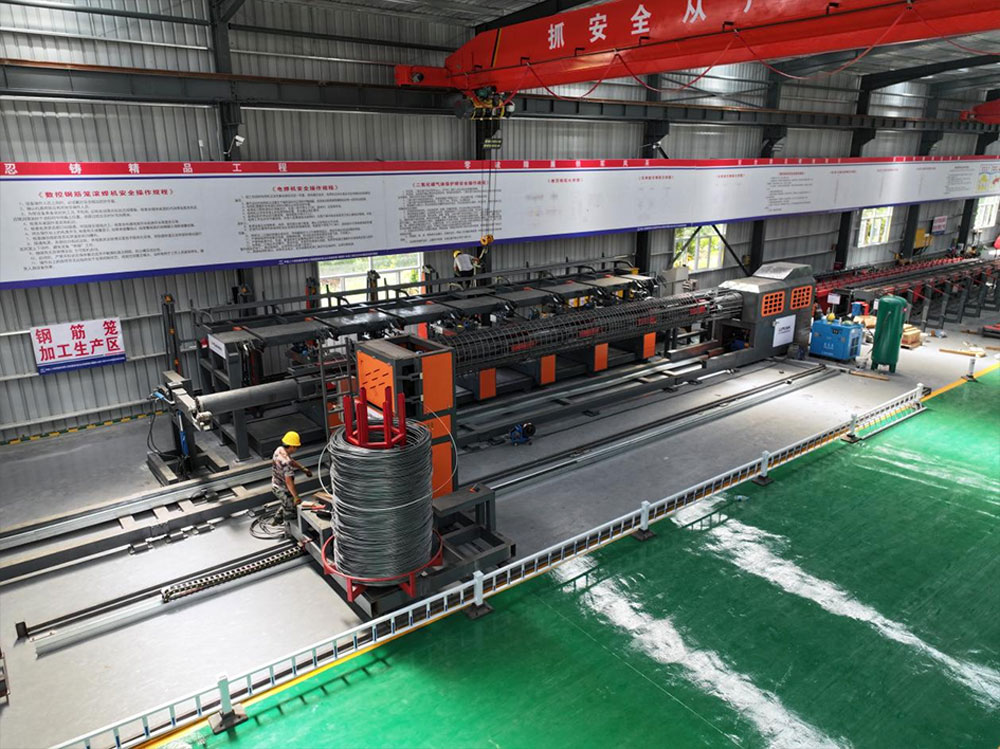

In collaboration with the China Railway 24th Bureau, Zhongji Luyuan is establishing an intelligent rebar processing facility that utilizes advanced smart equipment and automated transport systems to minimize manual operations and maximize productivity.

Industry-Leading Rebar Cage Welding Station

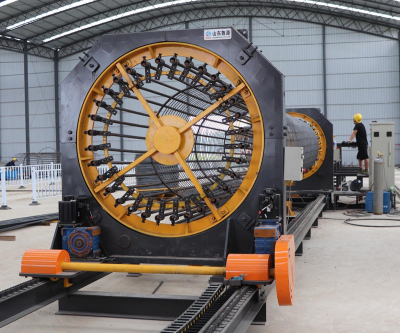

At the core of this facility is Zhongji Luyuan’s revolutionary rebar cage welding station, a next-generation solution that redefines efficiency standards in rebar manufacturing. This fully automated workstation integrates 8 advanced robotic welding arms, working in sync to execute all major steps—including automatic main bar feeding, precision alignment, high-accuracy detection, and seamless cage welding—without human intervention.

This innovation transforms what was once a complex, manual process into a streamlined production line, drastically improving output while reducing human error.

Intelligent Data, Smarter Construction

The rebar cage welding station is equipped with a smart data collection system that records the precise length of each main bar in every cage. This data-driven approach enables highly accurate downstream processing and has replaced the traditional double-cage splicing method. As a result, project management becomes more digitalized, traceable, and intelligent, realizing the vision of “Data-Driven Smart Construction.”

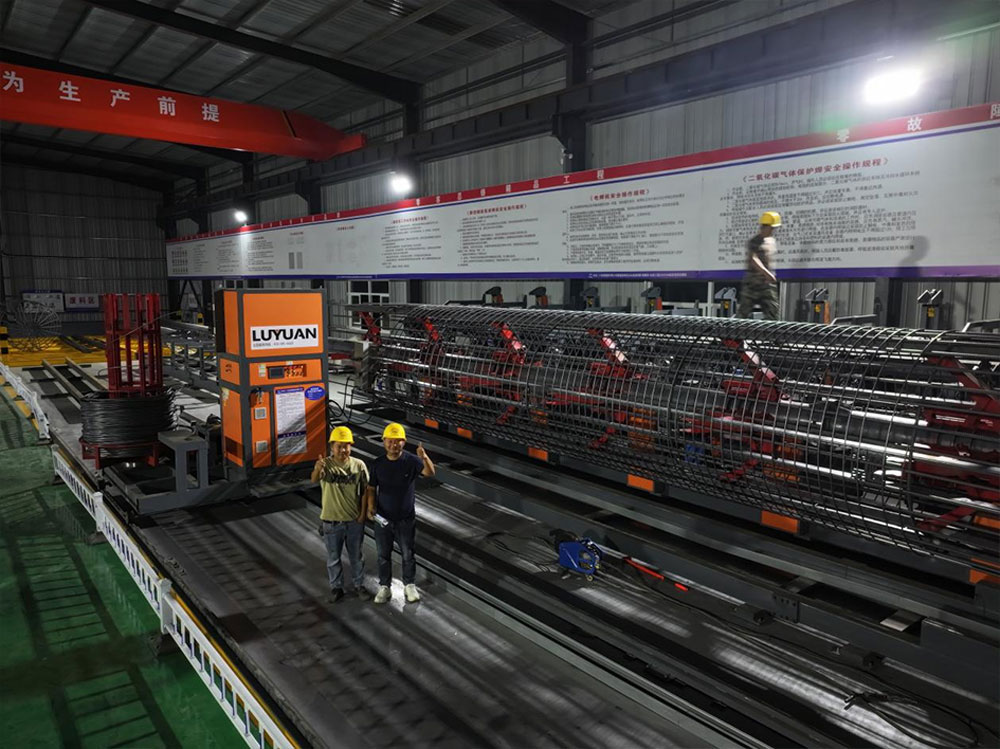

Manpower Efficiency and Versatile Design

Traditionally, rebar cage fabrication required 3–4 skilled workers. Now, with Zhongji Luyuan’s innovation, a single operator can manage the entire process, saving labor, reducing costs, and enhancing safety. This is not just a leap in production—it’s a transformation of the entire construction workflow.

Designed for maximum adaptability, the welding station supports both single and double main bars, and single or dual spiral wires, making it a highly flexible, multi-functional solution that meets the demands of diverse projects. This adaptability greatly enhances the station’s market competitiveness.

The launch of this intelligent rebar cage welding station marks a major milestone in the industrialization and automation of the construction sector. It reflects Zhongji Luyuan’s ongoing commitment to innovation, excellence, and the future of smart infrastructure development.