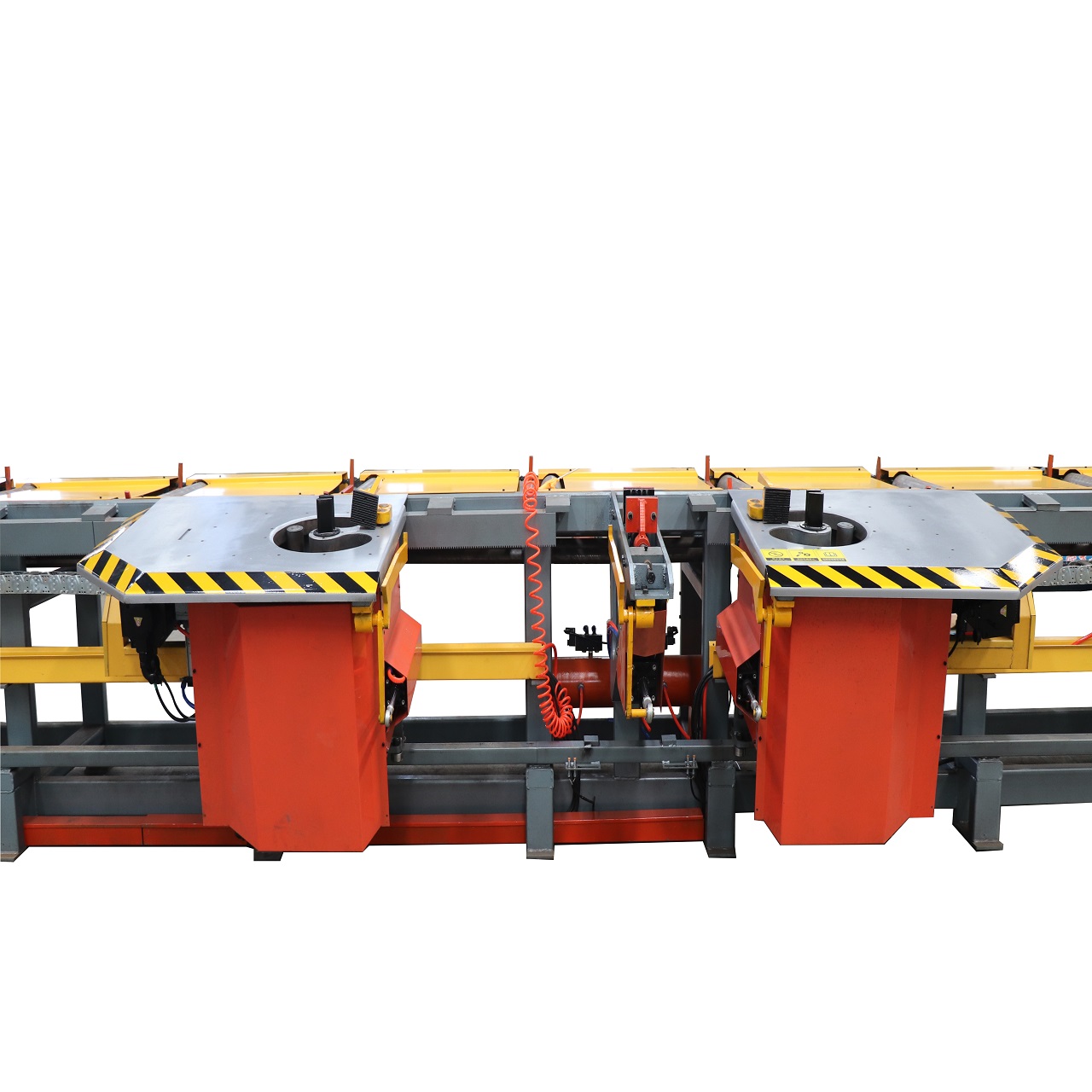

10mm Double Bending Machine

Product Details/Advantage:

1.Controlled by top-class brand servo motor. The head features rapid moving response and high accuracy of positioning.

2. With world top-class brand CNC control system, we realize automatic production and ensure practicality and long service life of equipment.

3. The bending head has compact structure. The bending moulds of different models are equipped. The bent rebar is of intensive range.

4.The bending platform adopts high-strength guide rail which will not be out of shape easily and is durable in use.

5. With humanized storing racks, the production is easy, and efficiency can be improved.

6. It can process many rebars at one time to increases efficiency.

7. It adopts unitary lifting and there is no need to dismantling when removal. It applies to fixed site manufacturing or frequently changing site for its simple installation.

8. High intensity and automatic storage rack on vertical rebar bending center.

10mm Double Bending Machine

Servo-Driven Precision for Rapid, Accurate Bending

CNC Control for Automated, High-Volume Production

Compact Design with Versatile Bending Capabilities

Heavy-Duty Construction for Long-Lasting Performance

Multi-Bar Processing for Unmatched Throughput

Applications & Industries Served

Key Benefits at a Glance

Upgrade Your Bending Capabilities Today

Contact us now to discuss customization options, request a demo, or get a quote tailored to your project requirements. Let’s bend the future of construction together!

Pre-sale Service

1. According to your requirements to help you design a reasonable solution,choose a reasonable equipment 2.In-depth explanation of customer service scheme by design experts.

Sale Service

1. Provide the video to help you to learn about how the device works.

2.Help you to know the details of the Key parts and our advantage.

After-sales Service

1. Guarantee for One year.

2. Quality problem, we will send you the accessories.

3. Free repair whole using life (without the freight and accessories charge)

4.24 hours maintenance response: timely feedback within 24 hours after acceptance of maintenance service.

5. Customer can enjoy lifelong value maintenance.

6. Professional and international experienced after-sales service team.

Packing Details : CNC bender center will be nude packed in container, the parts and tool will be packed in wooden case.suitable for long distance sea shipment.

Delivery Details : 7 days after prepayments.

CNC bending hoop machine

91.8% Response Rate

CNC cage making machine

91.8% Response Rate

Nc shear line of reinforcement

91.8% Response Rate