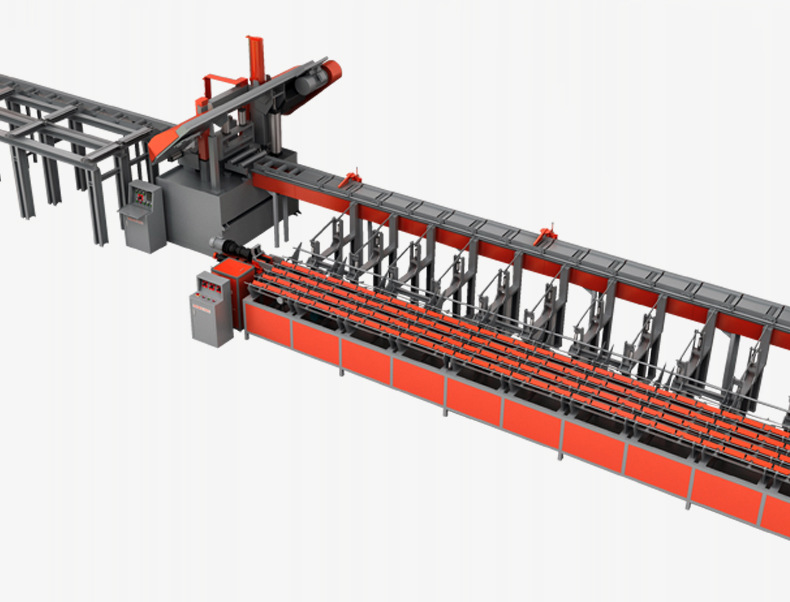

The fully automatic steel bar cutting, upsetting and threading production line integrates fully automated processes of cutting, upsetting, and threading, completing the transformation from raw steel bars to semi-finished products with threaded ends in the shortest time, significantly reducing process handover time.

The two core processes of cutting and upsetting are closely linked via an intelligent control system, which real-time monitors key parameters such as steel bar length accuracy and end upsetting dimensions. Abnormal conditions are automatically detected and trigger error correction mechanisms to ensure process quality stability.

The equipment is equipped with a user-friendly interface, supporting visual setup and adjustment of parameters such as cutting length and upsetting force. The modular production line can be flexibly disassembled into independent cutting units and upsetting-threading units for standalone use, adapting to different production capacity requirements. The advanced servo control system enhances both cutting positioning accuracy and upsetting-threading efficiency.

Full-process Automation Integration: Covers four processes: steel bar feeding, fixed-length cutting, end upsetting, and threading. High automation significantly reduces manual intervention and labor intensity.

Intelligent Cutting Module:

Equipped with a high-precision fixed-length cutting device, supporting precise cutting of steel bars within 1.5~12 meters, with length error controlled at ±1mm/m;

Continuously adjustable cutting feed speed adapts to efficient shearing of different diameter steel bars (Φ16~), with a cutting efficiency of 90 meters per minute.

Seamless Process Linkage:

The cutting equipment is directly linked to the upsetting-threading equipment via an intelligent conveying track. After cutting, steel bars automatically enter the upsetting station without manual handling, avoiding storage space occupation and inter-process loss;

The lateral feeding device, combined with the intelligent feeding mechanism, enables automatic material replenishment at the cutting station. When the next process is empty after processing, it automatically transports unprocessed steel bars to the cutting area.

Technological Advantages:

Integrated upsetting-threading design supports end upsetting and threading (maximum 80mm length) for steel bars with diameters of 16-40mm, meeting the high-precision requirements of mechanical connections for construction steel bars;

The hydraulic clamping system and air circuit control (0.8MPa pressure) ensure steel bar stability during cutting and upsetting, avoiding processing errors caused by offset.

Equipment Flexibility:

The cutting line and upsetting-threading line can operate independently, suitable for both large-scale assembly line production and small-to-medium batch processing;

Modular structural design facilitates later maintenance and function expansion, such as upgrading to fully automatic feeding robots or docking with MES production management systems.

Model: 600

Cutting Diameter Range: Φ16~ (suitable for hot-rolled ribbed steel bars and plain round steel bars for construction)

Steel Bar Cutting Length Range: 1.5~12 meters

Length Control Accuracy: ±1mm/m (error ≤1mm per meter of length)

Cutting Speed: 90 meters/minute (steel bar conveying speed, determining continuous production efficiency)

Clamping Method: Hydraulic automatic clamping to ensure no 晃动 (sway) during cutting

Main Motor Power: 4kW (cutting power system)

Supporting Devices:

Intelligent fixed-length sensor: Real-time calibration of cutting length via laser ranging or encoders;

Waste collection system: Automatically recycles steel bar ends from cutting to keep the work environment tidy.

(Additional cutting-related linkage parameters on top of original parameters)

Cutting-Upsetting Linkage Efficiency: Time from cutting completion to upsetting station feeding <5 seconds (depending on steel bar length)

Linkage Control Method: Industrial PLC programming control, supporting collaborative optimization of cutting and upsetting parameters (e.g., automatically adjusting upsetting pressure based on cutting length)

Suitable Post-Cutting Steel Bar Status: Supports direct upsetting of straight bars and fixed-length cut bars without secondary straightening.

Process Completeness: Clearly defines "cutting" as one of the core processes, supplementing the full process description of "feeding → cutting → upsetting → threading" to highlight the production line’s integrated functions.

Technical Detail Enhancement:

Adds "Intelligent Cutting Module" in "Product Features" to elaborate on cutting precision (±1mm/m), speed (90m/min), and other parameters;

Emphasizes the linkage mechanism between cutting and upsetting (automatic conveying, parameter collaboration) to reflect the production line’s systematic advantages.

Terminology Consistency:

Translates "Cutting" as "剪切" (for steel bar cutting) to distinguish it from "锯切" (sawing). If the original equipment includes sawing functions, "sawing" can be retained, but here the focus is on "cutting" as per the user’s request;

Supplements professional terms like "fixed-length cutting" and "hydraulic clamping" to align with mechanical processing industry standards.

Application Scenario Adaptation:

Highlights the cutting process’s suitability for construction steel bar processing (diameter/length range), clarifying the equipment’s application value in preprocessing for steel bar mechanical connections (e.g., end upsetting and threading for sleeve connections).

This translation fully presents the production line’s "cutting" function in terms of technical parameters, process linkage, and quality control, forming an organic whole with the original upsetting and threading processes to meet the user’s needs for describing the equipment’s full-process functions.

![Automatic Steel Bar Sawing, Upsetting, Threading And Polishing Production Line Automatic Steel Bar Sawing, Upsetting, Threading And Polishing Production Line]()

![Automatic Steel Bar Sawing, Upsetting, Threading And Polishing Production Line Automatic Steel Bar Sawing, Upsetting, Threading And Polishing Production Line]()

![Automatic Steel Bar Sawing, Upsetting, Threading And Polishing Production Line Automatic Steel Bar Sawing, Upsetting, Threading And Polishing Production Line]()

![Automatic Steel Bar Sawing, Upsetting, Threading And Polishing Production Line Automatic Steel Bar Sawing, Upsetting, Threading And Polishing Production Line]()