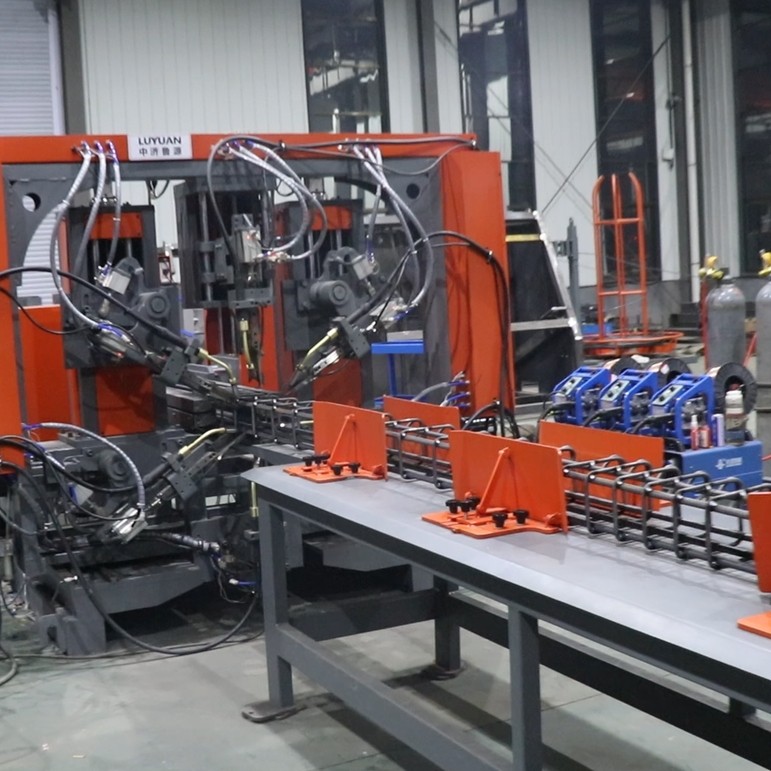

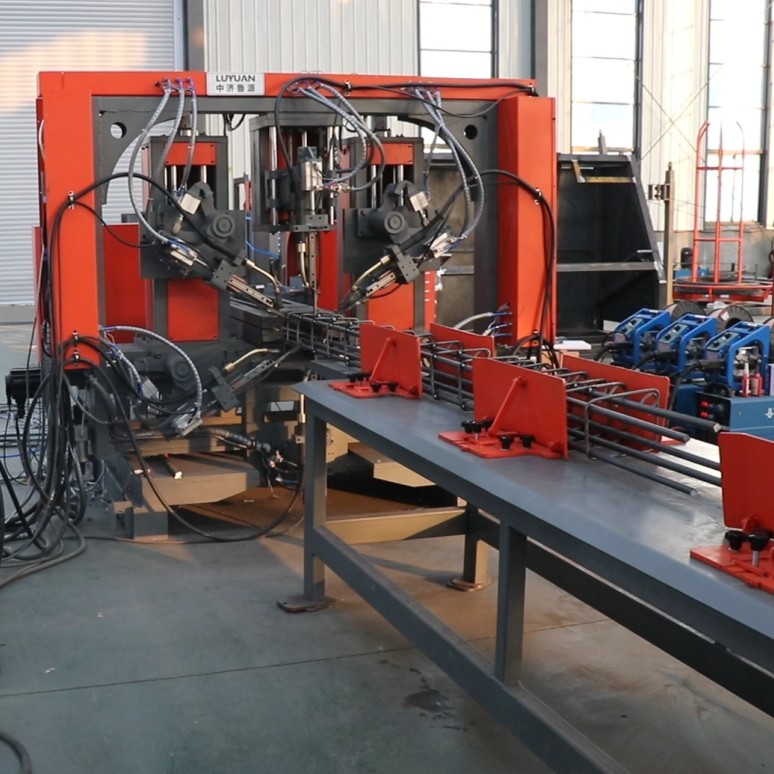

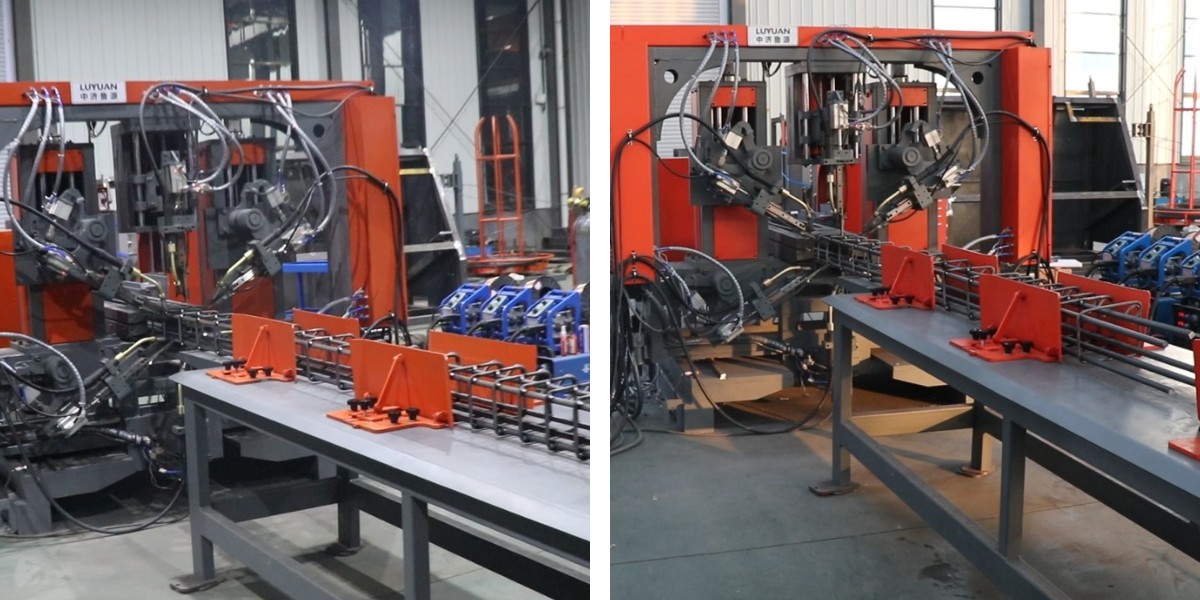

Auto Rebar Cage Assembly Machine

1.Automated Process: Replaces manual binding, enhancing efficiency.

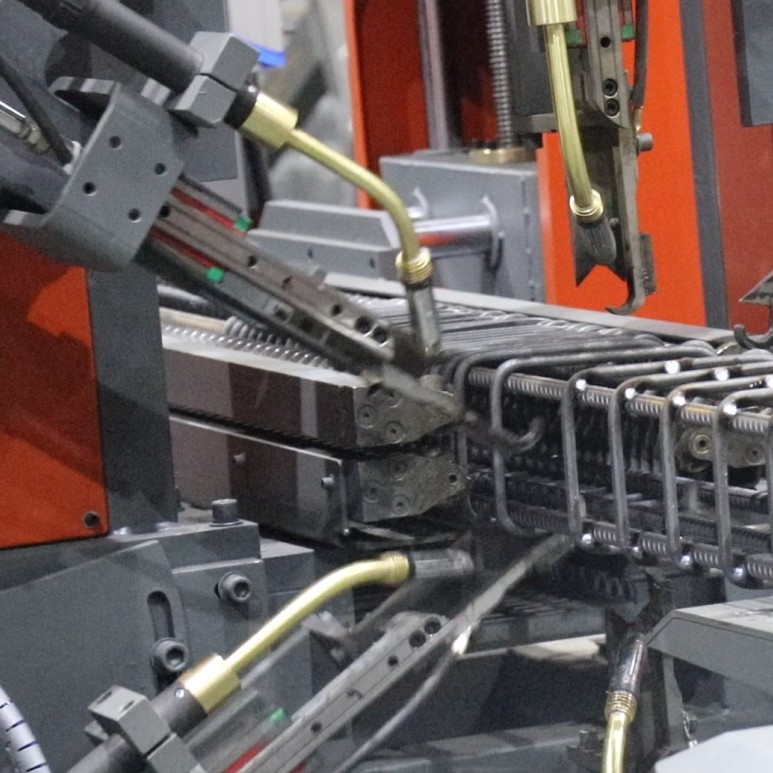

2.Precise Formation: Accurate assembly of special-shaped stirrup cages.

3.Customizable Spacing: Minimum 100mm, adjustable to customer needs.

4.Efficient & Reliable: Saves time and ensures long-term durability.

Product Description

The auto rebar cage assembly machine is an automatic welding and forming equipment designed for special-shaped stirrup steel cages. It offers a perfect alternative to manual binding, providing precise and efficient assembly. The minimum main bar spacing is 100mm, with the option for custom configurations based on customer requirements.

Parameters

Cage length | 6m,Customizable |

Winding bar type | Stirrup |

Main bar type | Bar |

Main bar number | 3-6pc, Customizable |

Diameter of main bar | 10-20mm, Customizable |

Stirrup diameter | 6-12mm, Customizable |

Stirrup profile | Triangles, rectangles, special shapes |

Stirrup spacing | ≥30mm |

Minimum distance between main bars | 100mm |

Welding manner | Gas shielded welding |

Gas pressure | ≤0.8MPa |

Power | 14.5KW |

Welding power | 100KW |

Number of operators | 1 person |

Production efficiency | 24 sections/10h,6m/section |

Occupied area | 16m×3m |

The steel cage forming machine is a special equipment used to produce the steel cage required in the construction of concrete piles, Bridges, and other construction projects. The correct operation of the steel cage forming machine is very important to ensure the quality and production efficiency of the steel cage.

Pre-Operation Checklist

1. Confirm the equipment status: Before the operator starts to operate the steel cage forming machine, it is necessary to check whether the equipment is in a normal state, such as whether the power is connected and whether the lubricating oil is sufficient.

2. Prepare raw materials: Prepare the required steel bars, welding wire and other raw materials, and classify and sort according to the production requirements.

3. Safety protection: The operator needs to wear protective equipment, such as safety helmet, gloves, goggles, etc., to ensure the safety during operation.

Start the steel bar cage forming machine correctly according to the requirements of the equipment operation manual to ensure the normal operation of the equipment.

Factory Show

Honors and Qualifications