CNC Rebar Bending Machine

CNC Rebar Bending Machine changes the traditional human-oriented multi-link steel bar processing mode, using CNC automatic production equipment, that the steel bar plate is formed by bending hoop at one time.

It greatly improves the production efficiency and steel bar processing precision, liberates labor and reduces material consumption. It is of high degree of automation. Hundreds of processing graphics can be entered in advance. And they can be picked up during processing.

China made luyuan machinery 16mm stirrup bender of wire and bar bending machine hot sale : Engineered for Precision Construction Solutions

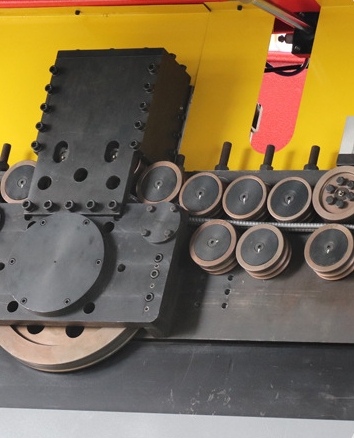

Innovative Blade System for Cost-Effective Maintenance

Servo-Driven Precision for Perfect Bends Every Time

Premium Components & User-Centric Operation

Double Wire Bending & Feeding System for Maximum Throughput

Key Advantages at a Glance

Precision: ±1mm linear accuracy, ±1° angular accuracy for intricate bending requirements.

Cost Savings: Reversible blades and durable components reduce maintenance and replacement costs.

Efficiency: Double wire system and automated controls maximize output while minimizing labor.

Versatility: Handles conventional rebar diameters and new grade 5 disk screw bars with ease.

Reliability: Imported parts and robust design ensure long-lasting performance in harsh environments.

Technical parameters

Single line processing capability:Φ5~12mm

Dual-line processing capability:Φ5~10mm

Angle of bend:<±180°

Center pin diameter:20~32mm

Maximum traction speed:110m/min

Maximum bending velocity:1200°/sec

Length accuracy:±1mm, Angular accuracy:±1°

Average power consumption:6kw/h

Working face rotation Angle:45°(90~135°)

Pieces Processed:≤2,Gas path pressure:≥0.6Mpa

Total power of the device: 28kw

Steel bar shape:

Modular Drawing library+Personalized editing

Gross machine weight:4800kg

Operating ambient temperature:-5~40℃

Main engine size:4550*1300*2100

1, warranty period 1 year from B/L date.

2, within warranty period you could get spare parts for free.

3, You could get free training in our factory.

4, 24 hours technical support by Email, calling or door-to-door service.

we are manufacturer of pile cage welding machine , CNC automatic steel bar bending machine,bending machine ,cutting machine, steel bar straightening machine etc.we also can supply setting up a new factory full line service . We have already exported various kinds of concrete pile ,pole and pipe concern making machines to overseas countries and regions such as Indonesia, Parkistan, Vietnam, Myanmar ,Korea,Malaysia ,South african,Mideast Southeastern Asia, etc..

Team

Our Team

Team

Our Team