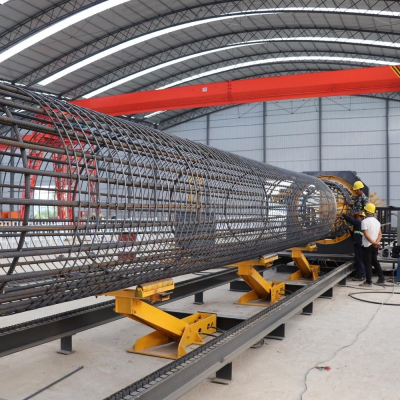

Recently, in the production workshop of a high-speed railway project department under China Railway Construction Corporation (CRCC) Fourth Engineering Group, with the completion of the final weld, China's first set of full-process intelligent steel cage welding workstations was officially put into operation. Jointly developed by Shandong Zhongji Luyuan Machinery Co., Ltd. and universities, this workstation integrates multiple core technologies such as robotic welding, visual positioning, and intelligent monitoring. It has completely transformed the traditional manual welding mode, increasing welding efficiency by more than 3 times and achieving a qualification rate of 99.8%, injecting new impetus into the high-quality construction of infrastructure projects.

![rebar cage machine rebar cage machine]()

Addressing Pain Points of Traditional Welding, Intelligent Equipment Emerges as the Times Require

As a core load-bearing component in infrastructure projects such as bridges, tunnels, and high-speed railways, the welding quality of steel cages is directly related to the structural safety of the project. For a long time, steel cage welding in China has mostly relied on manual operations, which has three major pain points: First, the labor intensity is high. Workers need to bend over for a long time and hold welding torches to work, which is prone to causing occupational diseases. Second, the efficiency is low. Manual welding of a single 12-meter-long steel cage takes 8-10 hours, which is difficult to meet the construction period requirements of large-scale projects. Third, the quality is unstable. Manual welding is affected by skill levels and fatigue, and welds are prone to defects such as slag inclusion and air holes, with a qualification rate of only about 85%.

"This high-speed railway project requires the production of nearly 2,000 steel cages with a total length of over 20,000 meters. The traditional mode simply cannot complete the task on schedule," said Manager Wang, head of the project department. To solve the construction challenges, the project department joined hands with scientific research institutions and spent 18 months on research, successfully developing the full-process intelligent steel cage welding workstation. This workstation realizes fully automated operations from steel bar straightening, cutting, grouping to welding and forming.

![rebar cage machine rebar cage machine]()

Multiple Technological Innovations, Building a "Smart Benchmark" for Welding

On-site observation by reporters showed that the workstation consists of four major modules: a steel bar preprocessing unit, an intelligent grouping unit, a robotic welding unit, and a quality inspection unit. The entire production process only requires 1 worker to set parameters and conduct auxiliary monitoring. "The core part is the robotic welding unit, which is equipped with 6 industrial welding robots. Combined with a visual positioning system, it can accurately identify the position of steel bars and automatically adjust the welding angle and speed," introduced Engineer Li, head of the R&D team.

The workstation’s innovations are reflected in multiple aspects: It adopts laser visual tracking technology, achieving a weld positioning accuracy of ±0.5mm and solving welding defects caused by deviations in steel bar spacing; It has developed an adaptive welding process database, which can automatically match welding current and voltage parameters according to the diameter and material of steel bars, ensuring consistent welding quality of steel cages of different specifications; It is equipped with a fume purification system, achieving a welding fume absorption rate of 98% and realizing green construction; A cloud-based monitoring platform has been built, allowing managers to check production progress, welding parameters, and quality data in real time, enabling full-process traceability.

"In the past, welding was accompanied by splashing sparks and pervasive fumes, and my whole body ached after a day’s work. Now I just need to press buttons in the control room, and the working environment is clean and comfortable," said Master Zhang, an experienced welder with 10 years of experience. According to actual measurements, the workstation only takes 0.5 hours to weld a single 12-meter steel cage, with a daily output of 8-10 sections. Compared with manual welding, its efficiency is increased by 3 times. At the same time, it eliminates the need for subsequent repair processes, reducing the comprehensive cost by 20%.

Leading Industry Upgrading, Assisting High-Quality Development of Infrastructure

The commissioning of this workstation has not only saved 205 days of construction period for the high-speed railway project and reduced labor cost expenditure by more than 3 million yuan, but also provided a replicable model for the intelligent upgrading of the infrastructure industry. Experts from the China Infrastructure Association stated that the intelligentization of steel cage welding is an important direction for the industrialization and digital transformation of the construction industry. The successful R&D of this workstation has filled the gap in China’s full-process automated steel cage welding equipment, promoting the transformation of traditional infrastructure construction to "intelligent manufacturing". It is understood that more than 10 infrastructure enterprises have come to inspect and discuss cooperation, and the workstation will be promoted and applied in projects such as expressways and urban rail transit. "In the next step, we will continue to optimize equipment performance, develop flexible production systems suitable for steel cages of different specifications, and expand functions such as AI quality inspection and digital twins to make the welding workstation more intelligent and efficient," said Engineer Li.

With the wide application of intelligent equipment in the infrastructure field, China’s infrastructure projects are moving towards the direction of "better quality, higher efficiency, and greener development", laying a solid transportation foundation for the high-quality development of the economy and society.