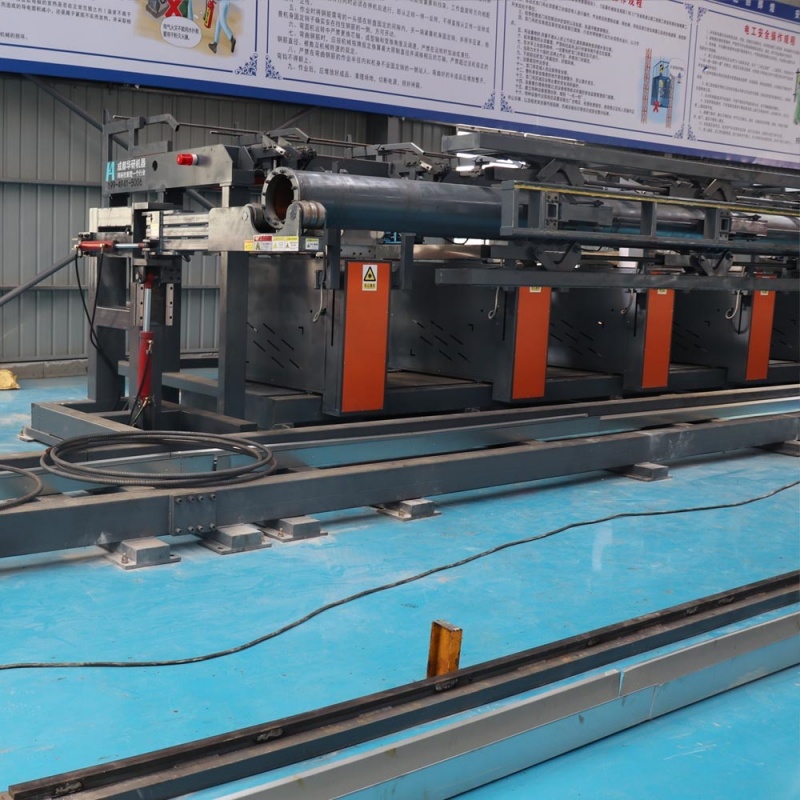

Full-Process Intelligent Steel Cage Welding Workstation

Efficiency Breakthrough: After adopting the workstation in an expressway project, the daily output increased from 3 units (manual) to 15 units; 800 steel cages were completed in 3 months, 1 month ahead of schedule;

Cost Savings: An urban rail transit project reduced 6 welding workers, saving over 1.2 million RMB in annual labor costs and approximately 300,000 RMB in annual weld repair material costs;

Industry Recognition: Currently serving 15 infrastructure enterprises and applied in key projects across 12 provinces in China.

I. Core Product Value: Solving Three Major Pain Points in Infrastructure Welding

The welding time for a single 12-meter steel cage is reduced from 8-10 hours to 0.5 hours;

The weld qualification rate is increased from 85% to 99.8%;

Labor costs for a single project are cut by more than 3 million yuan.

It has become an "efficiency engine" for infrastructure projects such as high-speed railways, expressways, and urban rail transit.

Energy Consumption: Total power of 55kW, 15% more energy-efficient than similar equipment; daily electricity cost (8 hours) is approximately 400 RMB;

Installation Cycle: Standardized installation process, with commissioning and put-into-operation completed within 7 days;

Adaptation Range: Steel cage diameter Φ600-Φ3000mm, length 6-24 meters; supports customized circular, square, and polygonal cross-sections;

Operation Threshold: Touchscreen + graphical interface; ordinary workers can operate independently after 2 days of training.

Pre-Sales: Free provision of site planning drawings (including water and electricity layout) and equipment selection plans; customized configuration based on project capacity requirements;

In-Sales: Deployment of 3 engineers for on-site commissioning; simultaneous provision of operation and maintenance training; distribution of Equipment Operation and Maintenance Manual;

After-Sales: 24-hour hotline response; on-site maintenance within 12 hours; 1-year warranty for core components (robots, motors); lifelong spare parts supply;

Upgrades: Free upgrades of AI intelligent quality inspection (automatic identification of weld defect types) and digital twin (3D simulation of production process) functions within 3 years after purchase.

Efficiency Breakthrough: After adopting the workstation in an expressway project, the daily output increased from 3 units (manual) to 15 units; 800 steel cages were completed in 3 months, 1 month ahead of schedule;

Cost Savings: An urban rail transit project reduced 6 welding workers, saving over 1.2 million RMB in annual labor costs and approximately 300,000 RMB in annual weld repair material costs;

Industry Recognition: Currently serving 15 infrastructure enterprises and applied in key projects across 12 provinces in China.