Small CNC Steel Bar Bending Machine: A Flexible and Efficient Choice for Medium and Small-Scale Construction

1. Lightweight Structure + Convenient Mobile Design

2. CNC Precision Bending System

3. Multi-Specification Adaptation + Overload Protection Mechanism

As a core equipment suitable for medium and small-scale projects, on-site emergency construction and home decoration reinforcement, the small CNC steel bar bending machine focuses on "lightweight design + precise control". It breaks through the site constraints of traditional large-scale equipment and can quickly complete multi-angle bending and forming of steel bars of different specifications. Providing efficient and reliable processing solutions for municipal maintenance, rural infrastructure, home decoration transformation and other scenarios, it has become the preferred equipment for small-batch steel bar processing.

I. Core Technical Highlights

1. Lightweight Structure + Convenient Mobile Design

2. CNC Precision Bending System

3. Multi-Specification Adaptation + Overload Protection Mechanism

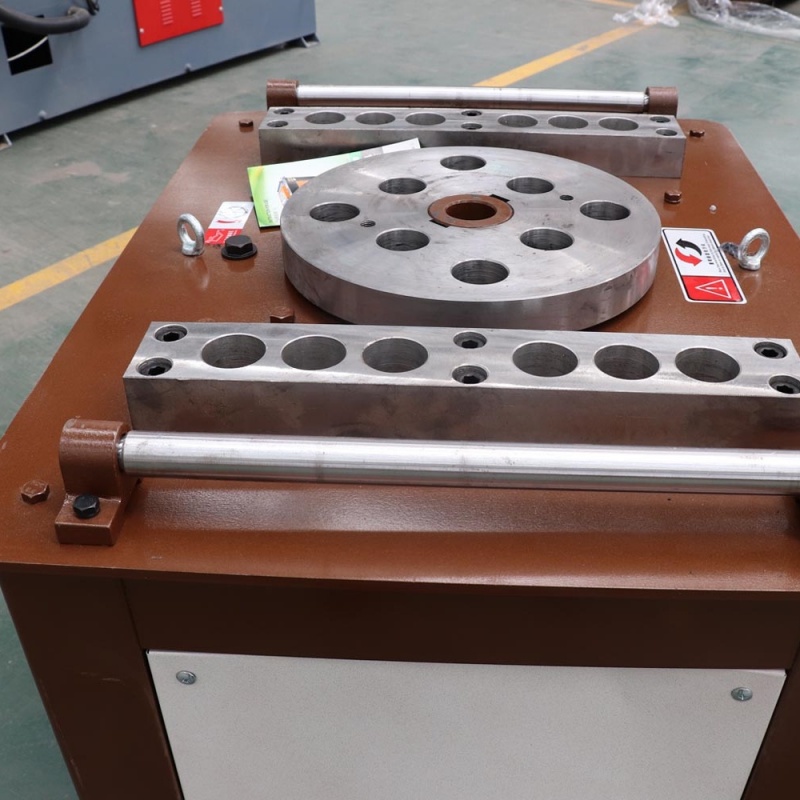

The innovative design of "adjustable chuck + graded power output" can adapt to Φ6-Φ25mm HRB335/HRB400 grade hot-rolled ribbed steel bars and Φ6-Φ32mm round steel, compatible with mainstream small-specification steel bar types in construction. It has a built-in intelligent overload protection module. When the steel bar diameter exceeds the standard or encounters materials with excessively high hardness, the equipment automatically shuts down and issues an acousto-optic alarm to avoid motor burnout and extend the service life of the equipment.

II. Key Performance Indicators

Performance Parameters | Data Indicators | Core Advantages |

|---|---|---|

Processing Range | Φ6-Φ25mm (ribbed steel bars), Φ6-Φ32mm (round steel) | Covers mainstream specifications for medium and small-scale construction |

Bending Speed | 3-5 seconds/time (90° bending) | 8 times higher than manual bending machines |

Angle Accuracy | ±0.5° | Meets high-precision forming requirements of specifications |

Rated Power | 2.2-3.0Kw | Driven by ordinary 220V civil electricity, suitable for scenarios without industrial electricity |

Continuous Working Time | 8 hours non-stop | Meets daily small-batch processing needs |

III. Application Scenarios and Practical Cases

1. Core Application Scenarios

Municipal and Home Decoration Fields: Suitable for guardrail steel bar processing in old community transformation, planting bar bending for indoor load-bearing wall reinforcement, and steel bar forming for kitchen and bathroom pipeline supports. It can work at close range without noise pollution;

Rural Infrastructure Scenarios: Used for steel bar processing of rural road curbstones and small water conservancy irrigation canal steel meshes. The lightweight and mobile feature adapts to field operations without fixed sites;

Emergency Repair Field: In emergency projects such as municipal pipe network rupture and bridge expansion joint maintenance, it quickly completes temporary support steel bar bending and shortens the repair cycle;

Small-Batch Processing of Prefabricated Components: When small prefabrication plants produce components such as lintels and cornices, it can flexibly match other small equipment to realize assembly line operations.

2. Typical Project Cases

In the renovation project of an old community in Beijing in 2025, the construction team used this small bending machine to complete the steel bar processing for balcony reinforcement of 3 buildings. The equipment was directly put into operation in the corridor, and more than 2,000 Φ12 steel bars were bent at 90° within 3 days, with a 100% angle qualification rate, saving the cost of 6 workers compared with traditional manual bending. In the quality improvement and reconstruction project of rural roads in Hebei, the equipment was matched with a mobile generator to realize field operations, completing 800 meters of curb steel bar processing in one day, and the efficiency was 5 times higher than that of manual equipment.