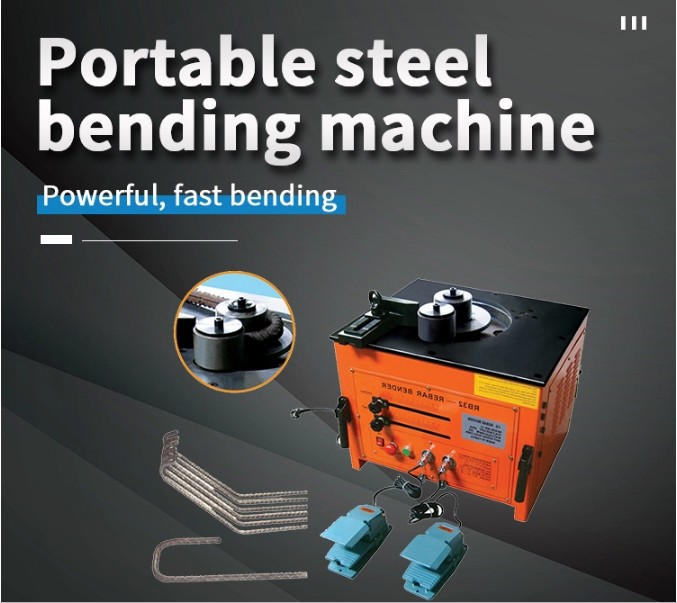

Small Steel bar Bending Machine

1. Efficient production, significantly improving operational efficiency

Automated operation: The electric drive achieves continuous bending without the need for manual adjustment of the frequency system, reducing manual intervention and increasing efficiency several times compared to traditional manual methods.

Quick response: The motor starts and stops quickly, coupled with a high-speed transmission system, it can quickly complete batch processing of single or multiple steel bars, especially suitable for projects with tight schedules.

2. High precision control to ensure engineering quality

Accurate angle: Through electronic control or mechanical limit devices (such as digital displays or angle adjustment discs), the bending angle (such as 90 °, 135 °, etc.) can be accurately set, and the error can be controlled within+1 ° to avoid rework.

High consistency: During batch processing, the bending shape and size height of each steel bar are uniform to ensure standardization of structural components.

3. Strong power, adaptable to complex needs

High torque output: The electric motor provides stable power and can easily bend steel bars with a wide diameter range (such as $6mm to 40mm), and even handle high-strength threaded steel.

Strong load capacity: Fearless of long-term continuous operation, avoiding performance degradation caused by overheating, suitable for high load requirements of large construction sites.

Construction Sites: Bending rebars for column stirrups, pile cages, or arch supports in bridges and tunnels

Metal Fabrication Shops: Crafting custom metal parts, furniture frames, or decorative elements

Maintenance Teams: On-site repairs for machinery, infrastructure, or equipment requiring quick steel bar shaping

DIY Enthusiasts: Home projects, garden structures, or small-scale metalworking tasks

Product Show

Pre-sale Service

1. According to your requirements to help you design a reasonable solution,choose a reasonable equipment 2.In-depth explanation of customer service scheme by design experts.

Sale Service

1. Provide the video to help you to learn about how the device works.

2.Help you to know the details of the Key parts and our advantage.

After-sales Service

1. Guarantee for One year.

2. Quality problem, we will send you the accessories.

3. Free repair whole using life (without the freight and accessories charge)

4.24 hours maintenance response: timely feedback within 24 hours after acceptance of maintenance service.

5. Customer can enjoy lifelong value maintenance.

6. Professional and international experienced after-sales service team.

CNC bending hoop machine

91.8% Response Rate

CNC cage making machine

91.8% Response Rate

Nc shear line of reinforcement

91.8% Response Rate