In the construction and steel processing industries, precision and efficiency in rebar handling are critical to project success. Introducing our High Performance 2-14mm Rebar Straightening and Cutting Machine—engineered to deliver unmatched accuracy, durability, and productivity for rebar processing tasks. Designed for 2-14mm diameter rebars, this machine combines advanced technology with user-friendly features, making it the ideal choice for construction sites, steel fabrication plants, and industrial workshops. Intelligent Microcomputer Control for Effortless Operation

Powered by a state-of-the-art microcomputer control system, this machine eliminates the need for manual input of roller circumference or encoder pulse counting. The intuitive program automatically calculates and adjusts parameters in real time, streamlining setup and reducing human error. Whether you're a seasoned operator or new to the equipment, the smart control system ensures quick mastery and consistent performance, saving time and enhancing operational efficiency.

Wide Encoder Compatibility with Precision Assurance

Equipped to connect with various encoder specifications, our machine offers seamless integration with different production setups. The high-precision control system guarantees millimeter-level accuracy in both straightening and cutting, ensuring every rebar meets strict dimensional standards. This reliability is essential for applications requiring uniform rebar lengths, such as concrete reinforcement, precast components, and structural steelworks.

Redundant Output Design for Uninterrupted Production

The single-pipe cutter features three independent output points, providing a fail-safe solution for continuous operation. If one output point encounters a fault, the machine automatically switches to an alternate point without downtime, minimizing production interruptions and maintaining workflow efficiency. This redundant design is especially valuable for high-volume processing, where every minute of downtime impacts project timelines.

Batch Processing with Smart Memory Functionality

Boost productivity with the ability to input up to 30 batches of length and quantity parameters simultaneously. The built-in computer memory stores these settings for future use, eliminating repetitive data entry and speeding up job setup. Whether you're processing mixed orders or large-scale projects, the batch memory feature simplifies management and reduces administrative overhead, making it perfect for high-throughput environments.

Automatic Straightening & Cutting with Digital Precision Featuring an electronic digital ruler system, the machine measures and adjusts rebar straightness in real time, ensuring optimal alignment before cutting. At the specified length, the automatic cutting system activates with precision, delivering consistent results without manual intervention. This fully automated process enhances product uniformity and reduces material waste, contributing to lower production costs.

Durable Construction for Harsh Industrial Environments

The specially designed circuit board is engineered to resist iron dust and debris, a common challenge in rebar processing environments. This protective feature prevents short circuits and extends the machine's lifespan, even in dusty or high-moisture settings. Combined with smooth mechanical operation, a low failure rate, and easy maintenance access, the machine offers reliable performance with minimal upkeep—keeping your operations running smoothly day after day.

Ideal for contractors, steel processors, and manufacturing facilities, our High Performance 2-14mm Rebar Straightening and Cutting Machine sets a new standard for productivity and precision. Invest in a solution that combines advanced technology with rugged durability—upgrade your rebar processing capabilities today.

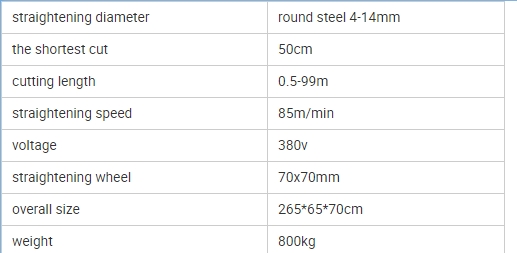

Frequency conversion 4-14mm steel wire rod straightening and cutting machine

Specification

![1745291708971612.png 微信截图_20250422111432.png]()

Our Company

![1745299040442029.jpg]()

FAQ

1. Q: Are you a factory or trading company?

A: We are a professional manufacturer with strong capability in research, development and manufacturing, you can not only get the factory price but also can enjoy the "ultra-high quality and professional design" unique to Zhongjiluyuan.

2. Q: Where is your factory located? How can I visit there?

A: Our factory is located in Jining City, Shandong Province, China. You can visit us by air to Qufu airport, or by the high-speed rail. All the customers, from home or abroad, are warmly welcome to visit us!

3. Q: Can you do OEM?

A: Yes, we can do OEM as client's requirement.

4.Q: All products have a warranty?

A:YES, Our warranty term is One Year.

5.Q:What about the delivery time?

A:Usually 7-15 days after down payment, the exact delivery time is according to the production season and order quantity.

6. Q: What is the biggest advantage of the company?

A: Stable Better Quality and Perfect Service .

Our company is a state high-tech enterprise, our rebar processing machinery are used in hundreds of infrastructure projects both with China and abroad.

We have the most complete after-sales service support system ,"8-level quality assurance system," truly lifelong maintenance, customer satisfaction is almost 100%.