Electric Stirrup Bending Machine

1. Efficient production, significantly improving operational efficiency

Automated operation: The electric drive achieves continuous bending without the need for manual adjustment of the frequency system, reducing manual intervention and increasing efficiency several times compared to traditional manual methods.

Quick response: The motor starts and stops quickly, coupled with a high-speed transmission system, it can quickly complete batch processing of single or multiple steel bars, especially suitable for projects with tight schedules.

2. High precision control to ensure engineering quality

Accurate angle: Through electronic control or mechanical limit devices (such as digital displays or angle adjustment discs), the bending angle (such as 90 °, 135 °, etc.) can be accurately set, and the error can be controlled within+1 ° to avoid rework.

High consistency: During batch processing, the bending shape and size height of each steel bar are uniform to ensure standardization of structural components.

3. Strong power, adaptable to complex needs

High torque output: The electric motor provides stable power and can easily bend steel bars with a wide diameter range (such as $6mm to 40mm), and even handle high-strength threaded steel.

Strong load capacity: Fearless of long-term continuous operation, avoiding performance degradation caused by overheating, suitable for high load requirements of large construction sites.

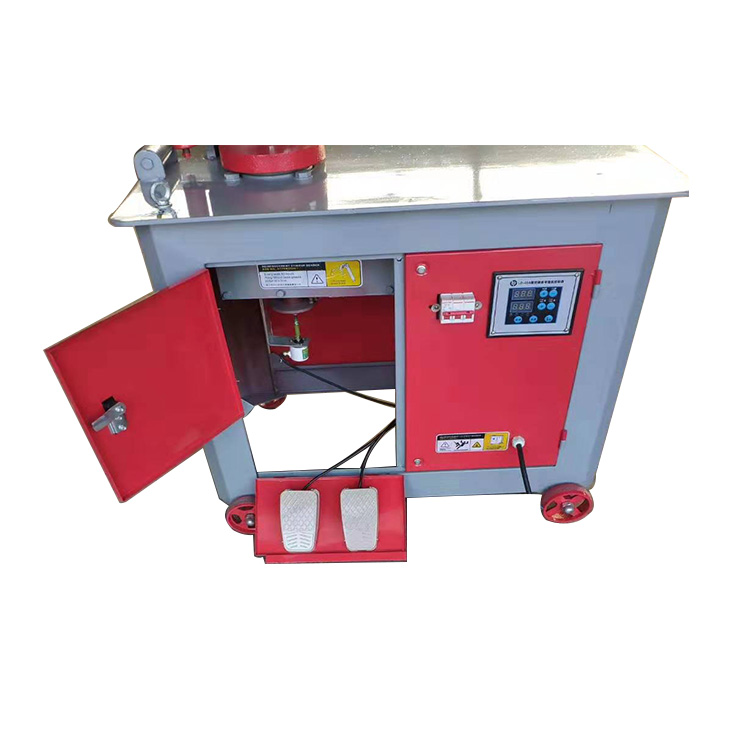

PRODUCT DESCRIPTION

Electric Stirrup Bending Machine

Transform your steel bar processing with the Electric Stirrup Bending Machine—a high-performance solution designed for precision bending of stirrups, hoops, and curved steel components in large-scale construction projects. Engineered for durability, efficiency, and ease of use, this machine is ideal for fabricating 360° arc-shaped rebars for bridges, tunnels, culverts, hydropower stations, and subway infrastructure, ensuring compliance with strict engineering standards.

Heavy-Duty Construction for Industrial-Grade Durability

Built to withstand the toughest job site conditions, our bending machine features three core advantages that set it apart:

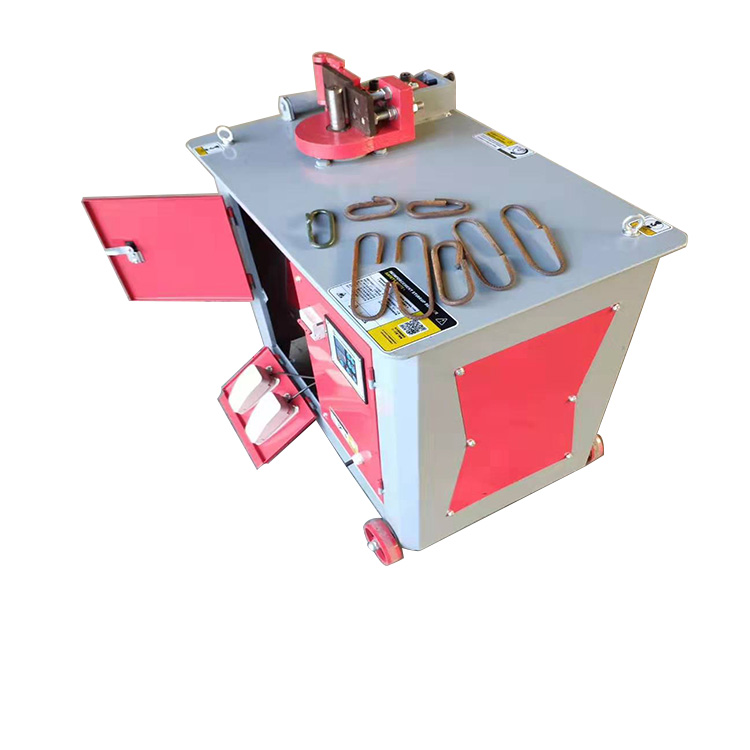

1. Triple-Durability Quenched Wheels

The driving and driven wheels are crafted from high-temperature quenched metal materials, undergoing a rigorous heat treatment process to enhance hardness and wear resistance. This advanced design increases durability by 300% compared to standard wheels, ensuring they maintain precision even after thousands of bending cycles. Whether forming stirrups for concrete reinforcement or complex curved components, the quenched wheels resist deformation and surface damage, reducing replacement costs and downtime.

2. Weighted & Thickened Fuselage for Unshakable Stability

The fully weighted and thickened steel fuselage provides a solid foundation for vibration-free operation, even when bending high-strength rebars. This rugged structure minimizes noise and ensures consistent bending accuracy, while its sturdy material composition drastically extends service life—withstanding accidental impacts and daily wear far better than flimsy alternatives. Trust this machine to deliver reliable performance in harsh construction environments.

3. High-Efficiency Copper Motor for Stable Power Delivery

Powered by a premium copper motor, the machine offers 2-3 times higher energy efficiency and smoother operation than conventional aluminum or hybrid motors. Copper’s superior conductivity ensures optimal heat dissipation, preventing overheating during continuous use and extending motor lifespan. The result? A stable, high-torque power source that enables fast bending speeds without compromising precision—perfect for meeting tight project deadlines.

Precision Bending for Complex Stirrup Shapes

Equipped with adjustable forming dies and a user-friendly control panel, the machine effortlessly creates 360° arcs, angles, and custom profiles for stirrups ranging from 4mm to 16mm in diameter (standard for most construction rebars). The intuitive design allows operators to set bending angles and radii with ease, while the precision alignment system ensures uniform results batch after batch—eliminating costly errors and material waste.

Versatile Applications for Large-Scale Projects

Ideal for:

Bridge & Tunnel Construction: Fabricating curved stirrups for precast segments and structural reinforcements

Subway & Rail Infrastructure: Forming hoops and arc-shaped rebars for tunnel linings and track foundations

Hydropower & Culvert Projects: Creating durable steel components for water diversion structures and drainage systems

Steel Fabrication Plants: High-volume production of standardized stirrups for commercial and residential buildings

The machine’s compact footprint and easy-to-maintain design make it suitable for both fixed workshops and mobile job sites, while its low noise operation ensures compliance with environmental regulations.

Products Show

Our Service

1, warranty period 1 year from B/L date.

2, within warranty period you could get spare parts for free.

3, You could get free training in our factory.

4, 24 hours technical support by Email, calling or door-to-door service.

Our Company

we are manufacturer of pile cage welding machine , CNC automatic steel bar bending machine,bending machine ,cutting machine, steel bar straightening machine etc.we also can supply setting up a new factory full line service . We have already exported various kinds of concrete pile ,pole and pipe concern making machines to overseas countries and regions such as Indonesia, Parkistan, Vietnam, Myanmar ,Korea,Malaysia ,South african,Mideast Southeastern Asia, etc..

Team

Our Team

Team

Our Team

Related Products

Customer Photos