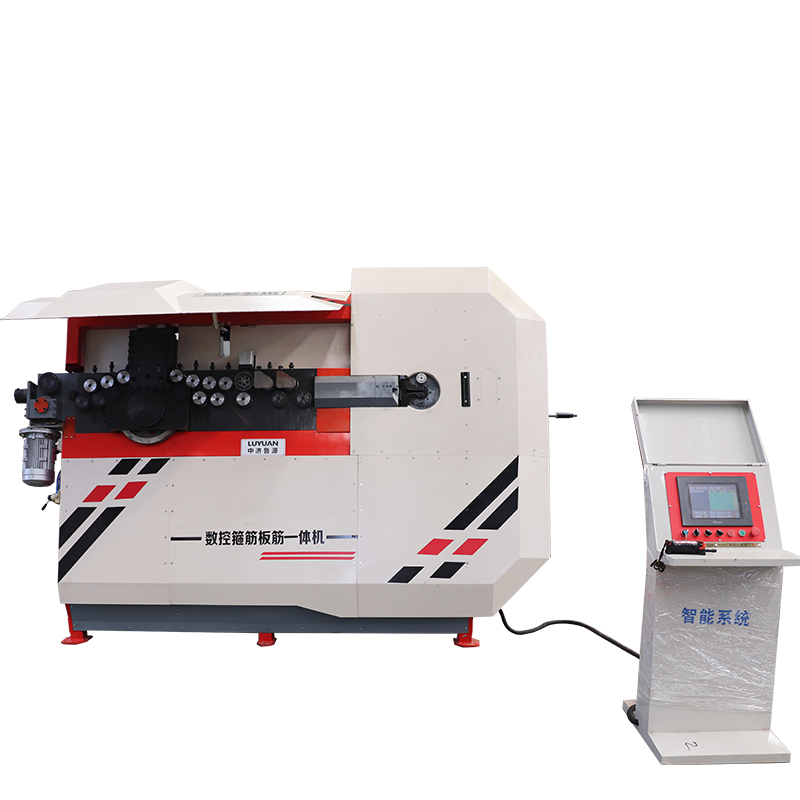

Rebar Automatic Stirrup Bending Machine

Feature

1, combine with horizontal and vertical straightening wheels, drive by Big 18.1kw SFC brand servo motor, make sure best accuracy when straightening rebar

2, bending spindle could rotating and telescope in high speed, could cut rebars very quick to get high bending precision.

3, large storage capacity can save many processing graphics,

4, PLC control system, Eview software, SFC servo motor.

5, straightening, measure length, bending, shear at same time, processing in high efficiency.

Product Details

Rebar Automatic Stirrup Bending Machine

Precision Straightening with Dual-Axis Technology

High-Speed Bending & Cutting for Maximum Throughput

Intelligent Control & Large Memory Capacity

All-in-One Automation for Streamlined Workflow

Key Components for Reliability

Applications Across Construction Sectors

Why Choose Our CNC Stirrup Bending Machine?

Ready to optimize your production? Contact us today for a custom quote, technical datasheet, or virtual demo—let’s bend the future of construction together.

Our Service

1, warranty period 1 year from B/L date.

2, within warranty period you could get spare parts for free.

3, You could get free training in our factory.

4, 24 hours technical support by Email, calling or door-to-door service.

Our Company

we are manufacturer of pile cage welding machine , CNC automatic steel bar bending machine,bending machine ,cutting machine, steel bar straightening machine etc.we also can supply setting up a new factory full line service . We have already exported various kinds of concrete pile ,pole and pipe concern making machines to overseas countries and regions such as Indonesia, Parkistan, Vietnam, Myanmar ,Korea,Malaysia ,South african,Mideast Southeastern Asia, etc..

Team

Our Team

Team

Our Team

Related Products

Customer Photos

Leave your messages