In the just-concluded September, at the 17th China (Beijing) International Construction Machinery, Building Materials Machinery & Mining Machinery Exhibition (BICES 2025), the "Steel Bar Prestressing Zone" located in Hall E4 attracted the attention of many industry insiders.

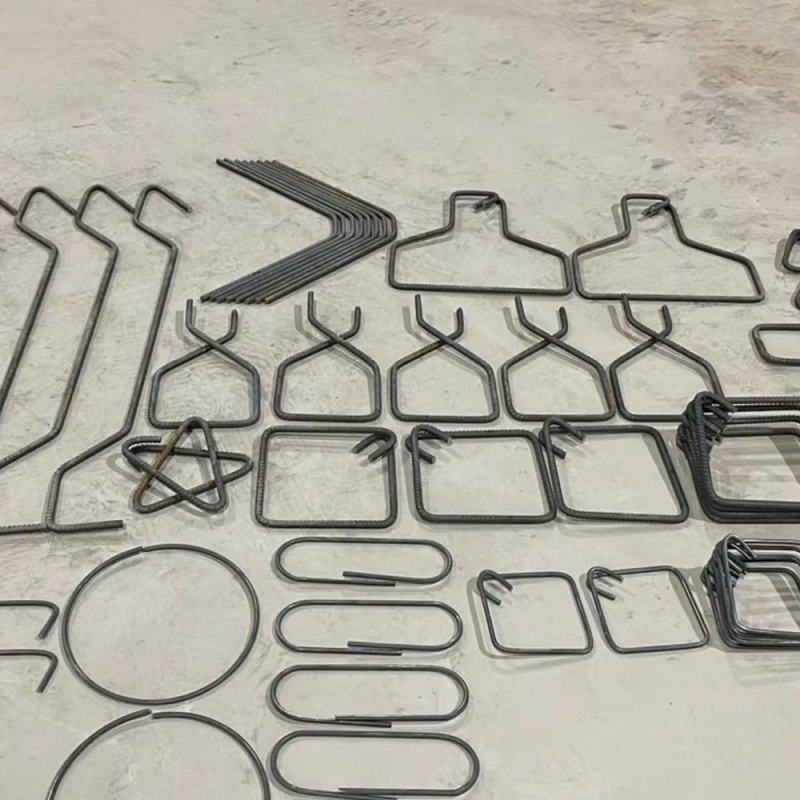

Nine industry enterprises, including Zhongji Luyuan and Hebei Jiaoyang Welding, jointly showcased intelligent steel bar processing equipment, outlining a future prospect of the industry's development towards high-end and intelligent advancement.

![rebar machine rebar machine]()

The steel bar processing equipment industry is ushering in an unprecedented technological transformation. In 2025, the global market scale of

automatic steel bar processing machinery continues to expand, with an average unit price of approximately $70,000 and a global sales volume of about 10,000 units.

These devices integrate numerical control systems, programmable settings, and robotic feeding systems, significantly improving processing accuracy, consistency, and production speed.

In August 2025, the formulation of China's first group standard in the field of digital construction of steel bar processing equipment—Technical Requirements for Digital Management Systems of Steel Bar Processing Equipment—was officially launched.

This standard will provide a unified and standardized technical basis for the industry, promoting the high-quality development of steel bar processing equipment towards intelligence and digitalization.

![rebar machine rebar machine]()

Among the recently announced innovative achievements, robot integration and automatic binding technologies are particularly eye-catching.

The "Intelligent Production Line for Robot-Integrated Prefabricated Beam Steel Bar Frames" developed by CCCC First Highway Engineering Group Fourth Engineering Co., Ltd. won the first prize in the 2025 Highway Transportation Intelligent Equipment Technology Innovation Competition.

By leveraging self-developed new-generation information technologies such as numerical control equipment, robots, and the Internet of Things (IoT), this production line realizes fully automated operations throughout the processing process of prefabricated beam steel bar frames.

In the field of nuclear power construction, in July 2025, China National Nuclear Corporation (CNNC) successfully launched the "Longgu No.1-II" automatic steel bar binding production line at the site of the Zhangzhou Nuclear Power Project.

This is China's first set of automatic binding systems designed for large-diameter steel bars (32mm~40mm) in nuclear power projects, integrated with five major modules: intelligent material list recognition, automatic material selection and feeding, precise laying, efficient binding, and digital information management.

In Tianjin, the "Longji Intelligent" intelligent manufacturing equipment for steel bar frames of railway simply supported box girders—jointly developed by the Assembly Technology Company of CRCC Bridge Engineering Bureau (a central enterprise stationed in Tianjin), China Railway Design Corporation, and Beijing Construction Machinery Institute—has been put into use in the Tianjin section of the Tianjin-Weifang High-Speed Railway.

Facing industry pain points, major enterprises are actively conducting technological research. Zhongji Luyuan Machinery Co., Ltd. recently obtained the invention patent authorization for "a straightening and bending integrated machine and a steel bar processing method."

This equipment can process steel bars of different diameters, significantly improving processing efficiency.

In the first half of 2025, Zhongji Luyuan invested 22.1033 million yuan in R&D, a year-on-year increase of 11.12%.

Hebei Zhijian Machinery Manufacturing Co., Ltd. focused on showcasing the intelligent steel bar straightening, bending, and welding forming production line for highway small box girders. This equipment realizes linked production by integrating multiple sets of intelligent steel bar processing equipment.

The three-in-one stirrup sheets of box girders produced by this line are formed through continuous welding without breakpoints, featuring a stable structure and an 8% reduction in raw material consumption.

The application of these intelligent equipments is generating significant benefits in practical projects. The flexible intelligent manufacturing production line for prefabricated box girder steel bar blocks developed by CCCC Second Harbor Engineering Co., Ltd. was applied in the Hubei Yanjing Yangtze River Bridge project, increasing the assembly efficiency of components by 1.5 times and achieving a concrete cover thickness qualification rate of over 96%.

At the intelligent beam factory of the Guangxi Cangrong Section 8 Project, China's first independently developed highly robot-integrated automatic prefabricated T-beam production line realizes the automatic processing and forming of steel bars from raw materials to steel bar frames, with each steel bar forming time taking only about 2 minutes.

90% of the processes of this production line are completed by robots, reducing the number of personnel by 80%.

The first national intelligent production line for prefabricated beam steel bars, independently developed by China Construction Third Engineering Bureau, successfully completed the erection of the first beam at the Project Section 2 of the Northern Section of the Wuhan Metropolitan Circle Ring Expressway. This marks a major breakthrough in the intelligent construction level of China's infrastructure field.

Inside the intelligent beam factory of the Guangxi Cangrong Expressway, robots accurately perform steel bar straightening, cutting, bending, and welding, with each steel bar frame forming time taking only about 2 minutes.

Compared with the traditional production mode, this production line reduces labor input by 80% while significantly improving the standardization level of construction and work safety.

From nuclear power construction to expressways, from high-speed railways to cross-river bridges, intelligent steel bar processing technology is transforming the construction industry we are familiar with at an unprecedented speed.

As the "14th Five-Year Plan" moves towards its conclusion, this wave of intelligentization will bring more possibilities to the traditional construction industry.