1250mm Steel Cage Rolling Welding Machine

1. control system: PLC, touch screen, inverter.

2. automatic wire feeding mechanism, the spacing can be adjusted online, the error is small, high molding quality.

3. frequency control drag cage institutions, high running accuracy.

4. with more automatic hydraulic feed rollers, to prevent steel cage deformation due to its own weight.

5. equipped with automatic feeding device, easy to operate and improve efficiency.

6. template using the template ring plus catheter combination, can be quickly replaced and transform the quantity of main steel cage wire .

7. straightening systems are made of high strength alloy material, high strength, anti-wear and improve the life of wearing parts

An advanced automated welding solution engineered for efficient steel cage production. Combining intelligent control systems with precision mechanical structures, it meets the demanding requirements of construction and bridge engineering, significantly enhancing welding quality and productivity.

On-line Adjustable Spacing: Real-time wire spacing adjustment during welding with error ≤ 0.5mm

High-Precision Forming: Stable wire feed rate with intelligent deviation correction ensures uniform welding without misalignment, delivering smooth surfaces free of welding nodules

Full-Spectrum Adaptability: Works with Φ4-Φ16mm wires, suitable for both thin-wall precision welding and heavy-duty skeleton reinforcement

Integrates photoelectric sensing material rack + servo pushing mechanism for continuous single/multi-cage loading, with a cycle time ≤15 seconds per load. One-button operation completes workpiece positioning and clamping, reducing manual handling loss and boosting daily output by 30%.

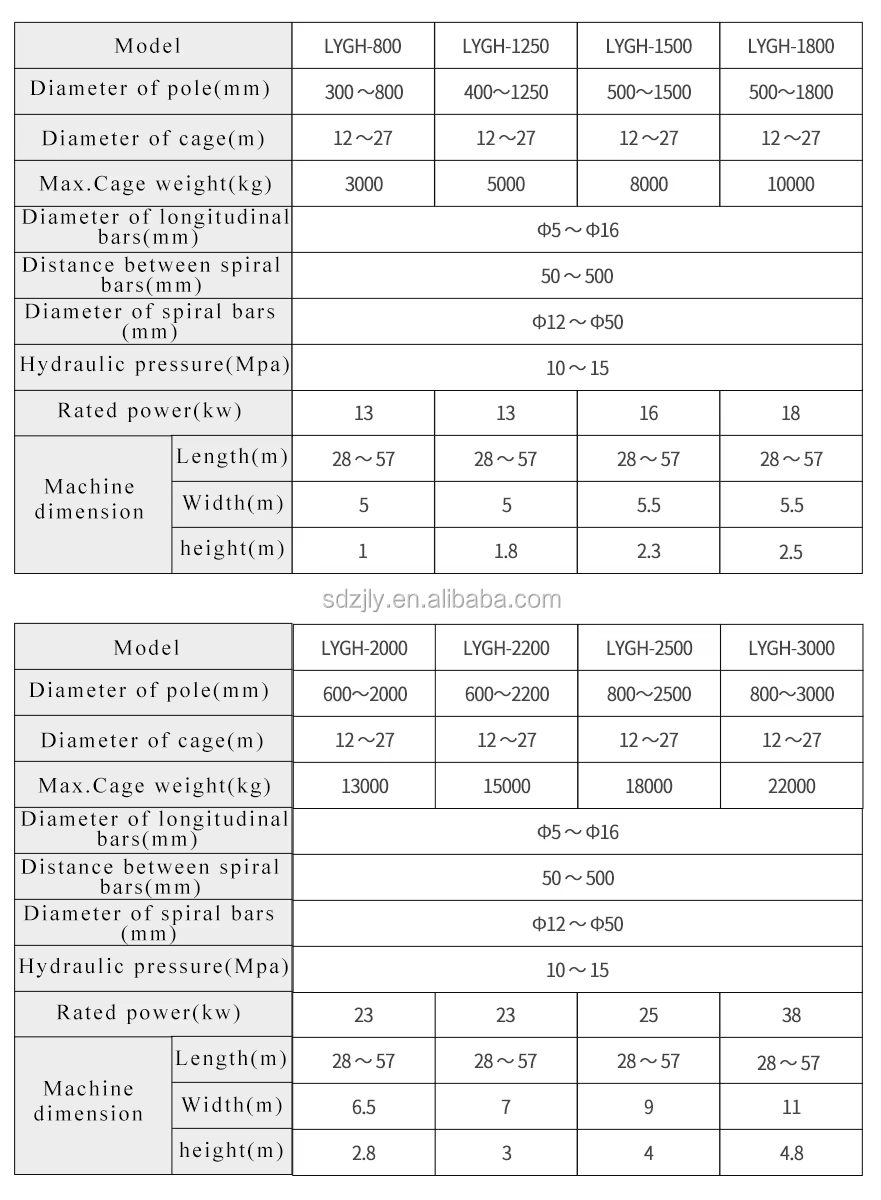

Machine Parameters

1, warranty period 1 year from B/L date.

2, within warranty period you could get spare parts for free.

3, You could get free training in our factory.

4, 24 hours technical support by Email, calling or door-to-door service.

We are manufacturer of pile cage welding machine , CNC automatic steel bar bending machine,bending machine ,cutting machine, steel bar straightening machine etc.we also can supply setting up a new factory full line service . We have already exported various kinds of concrete pile ,pole and pipe concern making machines to overseas countries and regions such as Indonesia, Parkistan, Vietnam, Myanmar ,Korea,Malaysia ,South african,Mideast Southeastern Asia, etc..

Team

Our Team

Team

Our Team