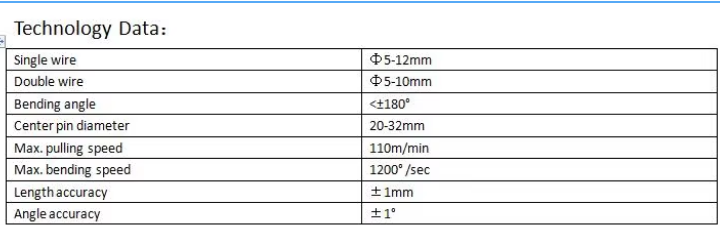

Durable Steel Bar Rod Stirrup Bender

China made luyuan machinery 16mm stirrup bender of wire and bar bending machine hot sale

Features:

construction, steel processing plants and other fields.

2. Function: It is a fully automatic CNC steel bar hoop bending machine, which is suitable for the forming and processing of

stirrups, hook bars and plate bars.

3. Function: 1. Rebar processing wire within 12 specifications. 2, 14 or 16 steel bar for processing.

4. Features: 1. Wire processing adopts curve straightening, which has all the advantages of curve straightening. 2. Automatic

step feeding is adopted for bar processing (magnetic feeding to be developed).

Durable Steel Bar Rod Stirrup Bender

Ladder Feeding System

A heavy-duty ladder-style conveyor ensures smooth, continuous material loading, guiding steel bars/wires precisely into the processing path.

Adjustable guides and anti-jam technology accommodate varying material diameters (6–16mm), reducing misfeeds and downtime—ideal for high-volume production environments.

Ergonomic height adjustment allows operators to load materials effortlessly, even in tight workspace conditions.

Hoop Bending Machine Host

The core processing unit is built with a reinforced alloy frame and precision gearbox, delivering stable, high-force bending without vibration.

Intuitive digital controls let operators input bending angles (0–180°) and dimensions directly, while quick-change dies enable seamless switching between stirrup shapes—rectangular, U-shaped, circular, and custom profiles.

Stainless steel (4–12mm), carbon steel (6–16mm), and deformed rebars (standard and high-strength grades), making it ideal for projects ranging from residential reinforcement to heavy infrastructure.

Integrated wire and bar processing eliminates the need for separate machines, reducing equipment costs and workshop clutter—perfect for contractors like Emily who need versatility for mixed-material projects.

Alloy Engine & Heavy-Duty Components: The premium alloy motor and heat-treated steel gears resist wear and tear, even after 10,000+ hours of operation in harsh conditions.

1-Year Warranty on Core Parts: We stand behind our machine’s reliability with a comprehensive warranty covering the motor, gearbox, and control system—giving users like David peace of mind.

Weather-Resistant Finish: A corrosion-proof coating protects the frame from rust and dust, ensuring consistent performance in outdoor construction sites or humid environments.

Wide Bending Range: Handles diameters from 6mm to 16mm and achieves a full 180° bend for complex stirrup designs, including the tight-radius hoops required for column reinforcements or beam structures.

±1° Angular Accuracy: Advanced servo control ensures uniform bends, meeting strict international standards (ISO, ASTM) and minimizing rework—critical for projects where structural integrity is non-negotiable.

Quick Setup: Die changes and parameter adjustments take less than 5 minutes, allowing rapid adaptation to new project specifications.

Comprehensive Machinery Testing: Rigorous load tests, speed calibrations, and safety inspections to ensure compliance with global quality benchmarks.

Video Outgoing Inspection: We provide detailed pre-shipment videos so customers can verify functionality and condition, just like David did for his recent order.

CE & ISO Certification: Built to meet European and international safety and performance standards, guaranteeing reliable operation in any market.

Time Savings: Processes up to 400 stirrups per hour with zero manual measurement errors, accelerating project timelines.

Cost Efficiency: Single machine replaces multiple tools for wire and bar bending, cutting equipment investment by 30%.

User Friendly: Low learning curve with intuitive controls—operators of all skill levels can start producing precision stirrups in minutes.

Versatile Applications: Perfect for residential floor slabs, commercial column reinforcements, bridge decking, and precast concrete elements.

Product Show

1, warranty period 1 year from B/L date.

2, within warranty period you could get spare parts for free.

3, You could get free training in our factory.

4, 24 hours technical support by Email, calling or door-to-door service.

we are manufacturer of pile cage welding machine , CNC automatic steel bar bending machine,bending machine ,cutting machine, steel bar straightening machine etc.we also can supply setting up a new factory full line service . We have already exported various kinds of concrete pile ,pole and pipe concern making machines to overseas countries and regions such as Indonesia, Parkistan, Vietnam, Myanmar ,Korea,Malaysia ,South african,Mideast Southeastern Asia, etc..

Team

Our Team

Team

Our Team