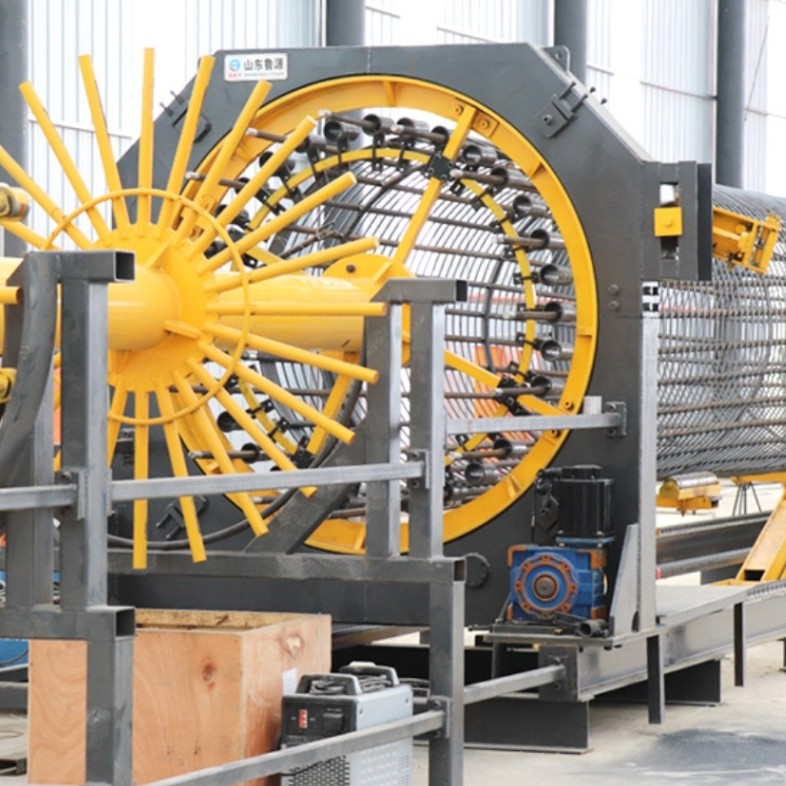

Steel Cage Bar Welding Machine

1.Automated Operation: PLC-controlled system eliminates manual steel cage binding.

2.Wide Application: Ideal for highways, high-speed rail, rail transit, power engineering, and water conservancy projects.

3.Mature & Stable: Reliable, proven technology for consistent performance.

4.User-Friendly: Easy to operate, enhancing productivity.

5.Flexible Configuration: Option to pair with a double gun automatic welding manipulator for increased efficiency.

Product Description

The steel cage production equipment controlled by PLC ended the history of manual binding of steel cages. It’s widely used in highway, high-speed railway, rail transit, power engineering, water conservancy projects and other projects. The equipment is mature, stable and easy to operate. Customers can choose the matching double gun automatic welding manipulator.

Parameters

Model | LYGH-1500 | LYGH-1800 | LYGH-2000 | LYGH-2200 | LYGH-2500 | LYGH-3000 |

Steel cage pile diameter | 500~1500 | 500~1800 | 600~2000 | 600~2200 | 800~2500 | 800~3000 |

Equipment power | 16KW | 18KW | 23KW | 23KW | 25KW | 38KW |

Occupied area(No side automatic welding) | 28m×6m | 28m×6m | 28m×6.5m | 28m×7m | 28m×9m | 28m×11m |

Occupied area(Including side automatic welding) | 28m×8.5m | 28m×8.5m | 28m×9m | 28m×9.5m | 28m×11.5m | 28m×13.5m |

Cage length | 12m Customizable | |||||

Diameter of main bar of steel cage | Φ16~50 | |||||

Diameter of winding bar of steel cage | Φ5~16 | |||||

Welding method of the winding bar | Welding robot or manual | |||||

Distance between two winding bars | ≤300mm | |||||

Hydraulic pressure | ≤16MPa | |||||

Gas pressure | ≤0.8MPa,Automatic welding gas | |||||

Welding power | 30KW,Double guns automatic welding | |||||

Number of operators | 1-2 persons,Double guns automatic welding 2-4 persons,Manual welding | |||||

Production efficiency | 8 sections/10h,Refer to the actual site environment | |||||

Factory Show

Honors and Qualifications