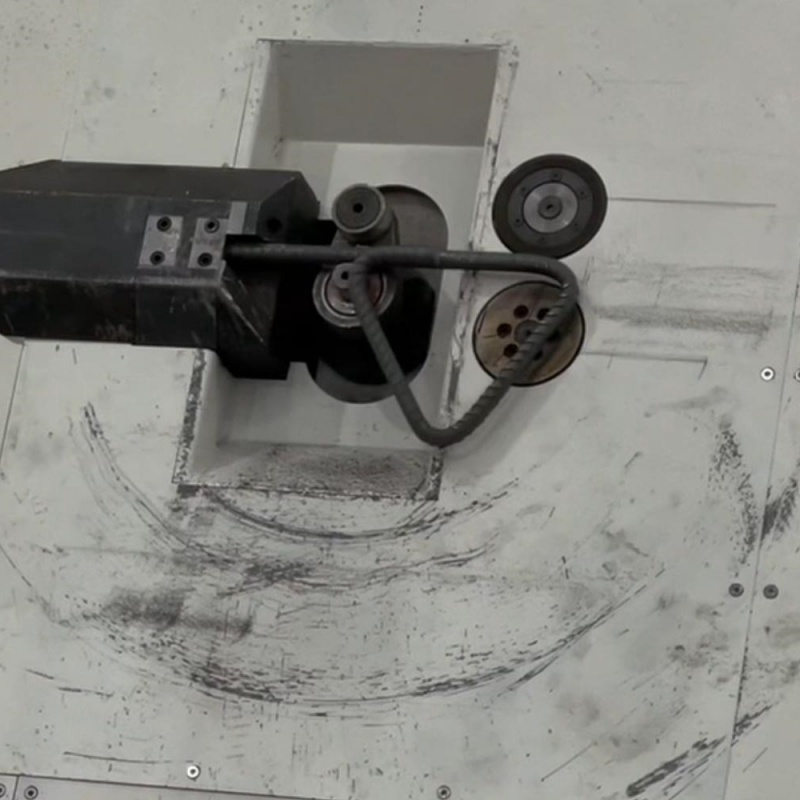

The CNC wire and bar integrated hoop bending machine is a multi-functional automatic steel bar processing equipment integrating servo drive, intelligent control and precision machinery. It is tailor-made to solve the pain point that traditional wire and bar hoop bending require separate machine operations. Integrating advanced CNC technology with the actual needs of construction, this equipment realizes integrated processing of the entire process of straightening, cutting and hoop bending for coiled wires and straight bars. It can flexibly produce various products such as stirrups, hooks and special-shaped bars, and is widely used in fields including housing construction, bridges, tunnels, prefabricated component factories and steel bar processing and distribution centers. It is a core equipment for improving the efficiency of steel bar hoop bending operations and reducing production costs.

![automatic stirrup bender automatic stirrup bender]()

I. Core Structure and Working Process

The equipment adopts a modular integrated design and consists of six core modules: dual-mode feeding system, intelligent straightening system, precision cutting system, multi-dimensional hoop bending system, finished product sorting system and CNC control system. It realizes seamless switching between wire and bar processing through intelligent linkage:

Dual-mode Feeding Stage: Equipped with dual feeding units of wire coil rack and bar feeding table, which can be flexibly switched according to the type of raw materials. The wire end adopts a hydraulic tension coil rack, suitable for Φ4-12mm coiled steel bars, with automatic wire tangling prevention function; the bar end adopts a V-shaped wear-resistant feeding roller table, suitable for Φ10-25mm straight bars, with a feeding speed of up to 60m/min. It supports multi-piece simultaneous feeding and realizes continuous material replenishment with the cooperation of intelligent material level detection.

Intelligent Straightening Stage: Adopts multiple sets of precision straightening wheels and servo straightening mechanism. When processing wires, the internal stress of the coil is eliminated through adaptive pressure adjustment; when processing bars, precise straightening is realized through positioning reference blocks. The straightening system has a built-in diameter identification module, which can automatically match straightening parameters according to the steel bar specifications. The straightening accuracy reaches ±0.5mm/m, effectively ensuring the subsequent processing accuracy.

Precision Cutting Stage: Equipped with a hydraulically driven high-speed cutting knife set with alloy blade design, which has fast cutting speed and flat and burr-free cutting surface. With the dual length control of servo motor and encoder, the cutting length accuracy reaches ±1mm, supporting arbitrary length setting in the range of 60-1000mm. It can realize single cutting or continuous batch cutting for steel bars of different specifications, and the cutting efficiency is 40% higher than that of traditional equipment.

Multi-dimensional Hoop Bending Stage: The core hoop bending mechanism is driven by a 360° rotating servo motor, equipped with quickly replaceable hoop bending dies, and supports hoop bending processing of any shape with less than 20 sides, including square, rectangular, rhombic, polygonal and various special-shaped stirrups. It automatically adjusts the hoop bending force according to the characteristics of wires and bars. The minimum hoop bending size of wires can reach 60×60mm, and the maximum hoop bending angle accuracy of bars is ±0.5°, with no springback or deformation during the hoop bending process.

Finished Product Sorting Stage: It is connected with the classified silo through an intelligent material turning arm, and automatically sorts the finished products into different silos according to the preset product specifications. It is equipped with a counting function that can display the output of each specification in real time, realizing the whole-process unmanned operation from raw material input to finished product collection.

II. Core Performance Parameters

| Parameter Category | Specific Indicators | Remarks |

|---|

| Processing Range | Wire: Φ4-12mm (round steel/threaded steel); Bar: Φ10-25mm (threaded steel) | Suitable for HRB335/400/400E/500 grade steel bars |

| Processing Accuracy | Length accuracy ±1mm; Angle accuracy ±0.5°; Straightening accuracy ±0.5mm/m | Dual control of servo motor + encoder |

| Production Efficiency | 1800-2200 pieces/hour (stirrups); Single-piece processing time ≤3 seconds | Measured value of Φ8 wire standard stirrups (300×300mm) |

| Power Configuration | Total power 22kW; Straightening servo motor 9.5kW; Hoop bending servo motor 5.5kW; Cutting motor 5.5kW | Energy-saving servo system, 25% lower energy consumption than traditional equipment |

| Equipment Specifications | Overall dimensions 3200×1200×1850mm; Total weight about 2.8 tons | Equipped with universal wheels for easy on-site movement |

| Function Configuration | Can store 100 sets of processing parameters; Supports special-shaped processing within 20 sides; Equipped with fault self-diagnosis system | 7-inch color touch screen operation |

III. Core Competitive Advantages

Dual Functions in One Line, Compatible with Multi-specification ProcessingIt breaks through the single raw material processing limitation of traditional equipment, realizing the same-line processing of Φ4-12mm wires and Φ10-25mm bars. No core components need to be replaced, and the raw material type can be switched only through touch screen operation. Compared with purchasing wire hoop bending machine and bar hoop bending machine separately, it can reduce equipment investment cost by more than 40% and save 50% of site occupation space. It is especially suitable for small and medium-sized processing enterprises and construction sites with limited space.

Full-process Automation, Sharp Reduction in Labor CostsThe whole process from raw material feeding to finished product sorting runs automatically. Only 1 operator is needed to complete parameter setting and raw material replenishment, and no manual participation is required in core processes such as straightening, cutting and hoop bending. Compared with the traditional manual + semi-mechanized processing mode, it reduces labor by more than 80%. Calculated by a single shift of 10 hours, it can replace the workload of 20-30 skilled workers, saving more than 1.5 million yuan in labor costs annually.

Precision Control, Minimized Material LossAdopting dual closed-loop control of servo drive + photoelectric detection, the cutting length error is controlled within ±1mm, the hoop bending angle accuracy reaches ±0.5°, and the product qualification rate is 100%, completely avoiding rework loss caused by size deviation. The continuous forming process makes the wire processing have almost no material head loss, and the bar processing tail material can be controlled within 50mm. The material utilization rate is increased by 3%-5% compared with traditional processes. Calculated by processing 1000 tons of steel bars annually, it can save more than 100,000 yuan in raw material costs.

Flexible and Efficient, Adapting to Diverse Production NeedsThe 7-inch color touch screen is equipped with an intelligent operating system, supporting graphic parameter input and storing 100 sets of processing parameters of different specifications. For multi-batch and small-batch production needs, parameter switching only takes 30 seconds. It can process square, rectangular, rhombic, polygonal and various special-shaped stirrups, meeting the steel bar processing needs of different projects such as housing construction, bridges and tunnels. It is suitable for steel bars of various strength grades from HRB335 to HRB500, and can realize multi-specification processing without replacing dies.

Durable and Stable, Controllable Operation and Maintenance CostsCore components are made of high wear-resistant materials: the straightening wheel is made of Cr12MoV alloy material, with a service life increased by 60%; the cutting blade is made of tungsten steel alloy, which can process continuously for more than 50,000 times after a single replacement; the hoop bending mechanism adopts a sealed design, which effectively prevents dust and dirt and reduces maintenance frequency. The equipment is equipped with a fault self-diagnosis system, which can monitor the operation status in real time and warn of faults. The annual failure rate is less than 5%, and the operation and maintenance cost is 20% lower than that of similar products.

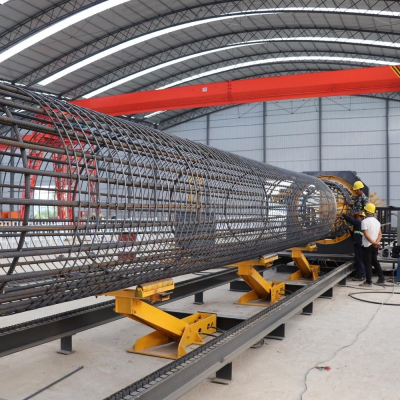

IV. Application Scenarios and Successful Cases

This equipment is suitable for various construction engineering scenarios, especially for stirrup processing in housing construction projects, special-shaped bar processing in bridges and tunnels, standardized steel bar processing in prefabricated component factories, and multi-specification batch processing in steel bar processing and distribution centers. At present, it has been successfully applied in projects such as a affordable housing project of China Construction Fifth Engineering Bureau, a tunnel project of China Railway 17th Bureau Group, and a large prefabricated component factory. In the prefabricated component factory case, the equipment produces more than 20,000 standard stirrups per shift per day, the material loss rate is reduced from 8% of the traditional process to 3%, saving more than 2 million yuan in costs annually. The product accuracy fully meets the requirements of the national Code for Acceptance of Construction Quality of Concrete Structure Engineering.