CNC Steel Bar Horizontal Bending Center

Anti-noise transmission roller table design provides safety and environmental protection. The main machine adopts no-backlash meshing technology for accurate positioning and no noise. Large stainless steel panel design makes the curved steel bar more stable. The design technology of automatic blanking mechanism saves time and effort. The crank type steel bar lifting and transferring mechanism is set up to provide maximum convenience for the operator's work. Inclined face structure, makes loading and unloading operation convenient and safe.

Angular bending velocity: 48°~72°/s

Moving speed of the bending machine: 0.5~1m/s

Anti-noise transmission roller table design provides safety and environmental protection. The main machine adopts no-backlash meshing technology for accurate positioning and no noise. Large stainless steel panel design makes the curved steel bar more stable. The design technology of automatic blanking mechanism saves time and effort. The crank type steel bar lifting and transferring mechanism is set up to provide maximum convenience for the operator's work. Inclined face structure, makes loading and unloading operation convenient and safe.

Bending bar diameter | 10mm | 12mm | 14mm | 16mm | 18mm | 20mm | 22mm | 25mm | 28mm | 32mm | 40mm | 50mm | |||||

Bending quantity | 6 | 6 | 5 | 5 | 4 | 3 | 3 | 2 | 1 | 1 | 1 | 1 | |||||

Angular bending velocity | 48°~72°/s | ||||||||||||||||

Moving speed of the bending machine | 0.5~1m/s | ||||||||||||||||

Power supply | 380V 50Hz | ||||||||||||||||

Total power | 27.7KW | ||||||||||||||||

Actual power consumption | 12kw/h | ||||||||||||||||

Maximum bending Angle | Upbend:0~180° | Minimum curved edge size | Φ12mm | ||||||||||||||

Upbend:0~-120° | Φ1100mm | ||||||||||||||||

Minimum length of bent edge | 80mm | Maximum curved edge size | 10000mm | ||||||||||||||

Minimum bending bar length | 1250mm | ||||||||||||||||

Compound bend (up or down) | Φ10~32mm | Single bend | Φ36~50mm | ||||||||||||||

Factory Show

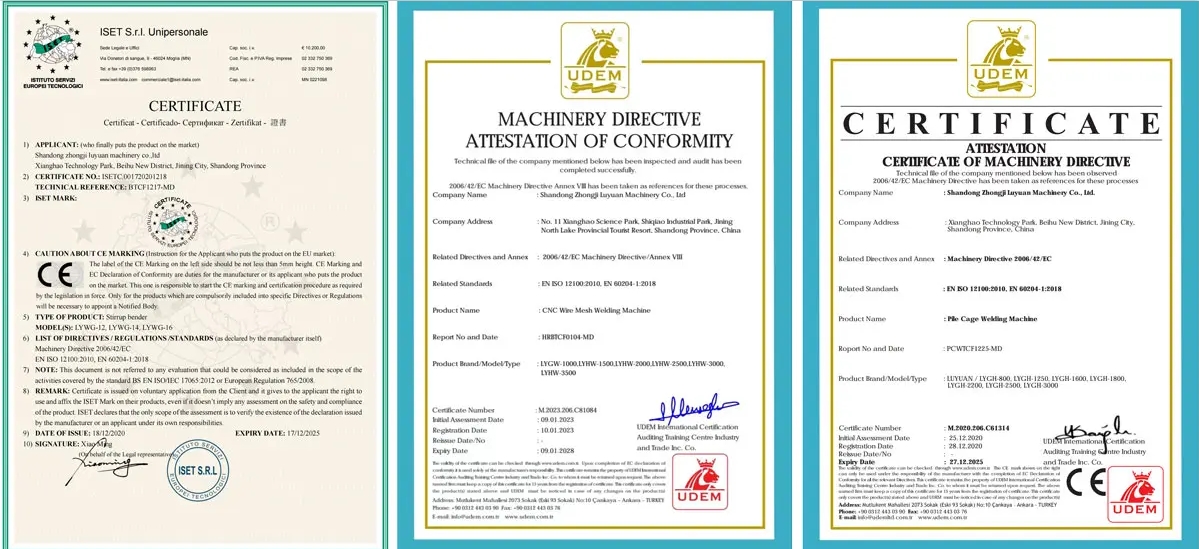

Honors and Qualifications