CNC Steel Bar Bending Machine, Fully Automatic Intelligent Equipment Leading the Innovation of Steel Bar Processing

Traditional manual processing of 1,000 standard stirrups requires 8-10 people to work together for one day. However, a single CNC steel bar bending machine only needs 1-2 operators, which can process 2,000 standard stirrups per hour, with a maximum daily output of 12,000 pieces, equivalent to the workload of 10-15 skilled workers. According to the application data of the Minmetals 23rd Metallurgical Xinxang Chemical Project, after deploying the WGT-D3 CNC bending machine, the daily processing volume of raw steel bars increased from 1 ton to 10 tons, and a 2-person team can replace the traditional 20-30 person team, saving more than 800,000 yuan in labor costs per project per year.

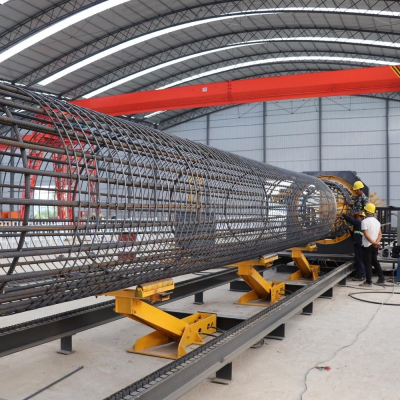

As a core equipment for the intelligent transformation of the infrastructure and construction industries, the CNC steel bar bending machine is tailor-made for stirrup processing in scenarios such as building beams and columns, bridge guardrails, and municipal utility tunnels. By virtue of industrial-grade PLC numerical control system and high-precision servo drive technology, it realizes the full-process automation of steel bar straightening, length fixing, bending forming and cutting, completely replacing the traditional manual bending mode. It solves the industry pain points of low efficiency, large precision fluctuation and serious material waste in manual processing. Currently, it has been widely applied in key projects such as the Minmetals 23rd Metallurgical Xinxang Chemical Project and high-speed railway bridge construction, and has become a standard equipment in intelligent steel bar processing plants.

Core Configuration: Modular Structure Lays a Solid Foundation for Performance

Intelligent CNC Control System: Equipped with an industrial-grade PLC controller and a 10-12 inch high-definition touch screen, it has built-in 500+ sets of standardized stirrup graphic templates. It supports one-key setting of parameters for rectangular, circular, special-shaped and 3D complex stirrups. New operators can work independently after 1 hour of training. High-end models are compatible with the BIM-MES collaborative management system, which can upload processing quantity and precision data in real time to realize visual management of project progress and meet the digital needs of modern construction.

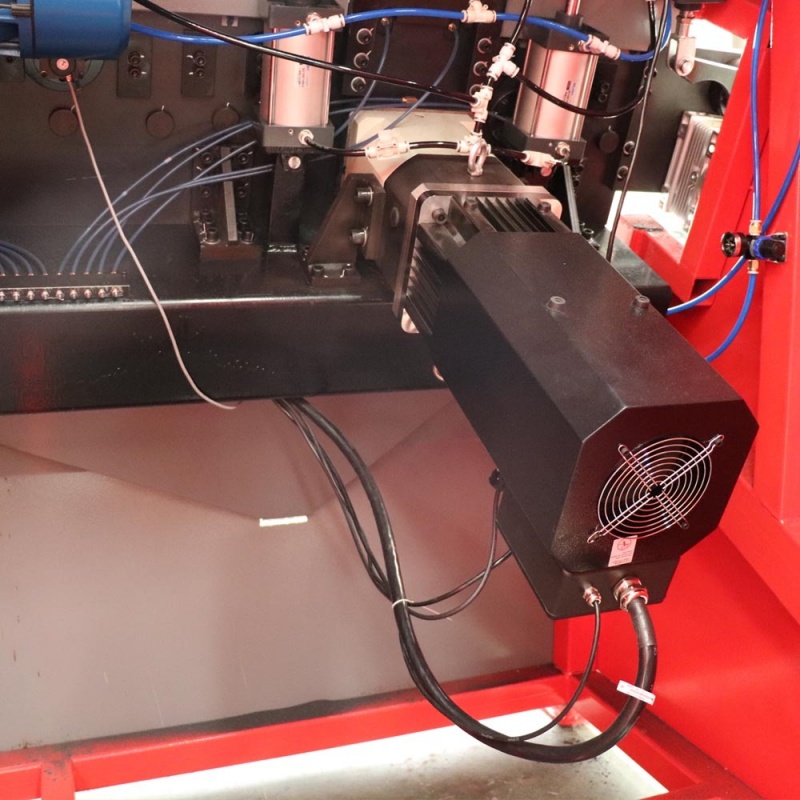

Precise Processing Execution Unit: Adopting a horizontal + vertical double straightening wheel system, combined with 4 sets of traction wheels and high-power Dongling servo motors, it realizes stress-free straightening of Φ5-Φ16mm coiled round steel and deformed steel bars. The straightening precision is 60% higher than that of traditional equipment. The core bending mechanism adopts high manganese steel quenching and tempering technology, equipped with 3D intelligent linkage bending technology, which can realize 0-180° two-way bending. The bending speed reaches 1050°/second, and the single-point bending error is controlled within ±0.5°, far exceeding the industry average level.

Efficient Production Auxiliary System: Equipped with 2 sets of 2-ton enhanced pay-off racks, it supports double-line synchronous feeding processing and can handle 2 Φ5-Φ12mm steel bars at the same time. The production efficiency is 80% higher than that of single-line equipment. Some models are equipped with automatic return and material shifting mechanisms, which can flexibly switch between stirrup, hook bar and slab bar processing modes to realize "one machine for multiple uses" and greatly reduce equipment investment costs.

Stable Bearing and Protection System: The machine body is formed by integral welding of thickened steel plates, and the core load-bearing components are strengthened by quenching. It can operate continuously for 24 hours without failure in complex construction site environments such as dust and vibration, with a designed service life of 8-10 years. It has built-in emergency braking, overload protection and oil fume purification devices, which meet the standards of green construction and safe production.

Core Performance Advantages: Multi-dimensional Empowerment for Quality and Efficiency Improvement

1. Efficiency Multiplication: 80% Direct Reduction in Labor Costs

2. Millimeter-level Precision: Zero Rework to Ensure Project Quality

3. Flexible Adaptability: Seamless Switching Between Multiple Scenarios

4. Energy Saving and Durability: 30% Further Reduction in Operation and Maintenance Costs

Core Technical Parameters

Parameter Item | Standard Model (SGW12D Series) | High-end Model (WGT-D3 Series) |

Processing Steel Bar Diameter | Single-line Φ5-13mm; Double-line Φ5-10mm | Single-line Φ5-16mm; Double-line Φ5-12mm |

Bending Angle Range | 0-180° (Two-way) | 0-180° (Two-way, supporting 3D bending) |

Processing Precision | Length ±1mm; Angle ±1° | Length ±1mm; Angle ±0.5° |

Production Efficiency | 1500-2000 pieces/hour (Standard stirrups) | 2000-2500 pieces/hour (Standard stirrups) |

Traction Speed | 80-100m/min | 100m/min |

Total Power | 20-30kW | 48-50kW |

Overall Dimension | 8000×1600×1800mm | 8500×1800×2000mm |