As a core structural building material known as the "backbone" of reinforced concrete structures, steel bar plays an irreplaceable role in construction engineering. Endowed with excellent tensile strength and fatigue resistance, it is widely applied in both reinforced concrete structures and prestressed reinforced concrete structures—supporting and reinforcing everything from beam-column frames of high-rise residential buildings, load-bearing pile foundations of cross-river bridges, to railway sleepers and airport runway foundations. Its quality and application directly determine the safety, stability and service life of building structures, making it an indispensable material in modern engineering.

In 2010, China's crude steel output exceeded 600 million tons, a milestone that not only demonstrated the strong strength of China's iron and steel industry but also reflected the booming development of domestic infrastructure and real estate sectors. Corresponding to this was a huge steel bar consumption market: industry statistics showed that the annual consumption of steel bars in the country's concrete structures had exceeded 90 million tons at that time, accounting for more than one-third of the annual steel bar consumption of major economies worldwide. Among them, the demand for steel bars in highway construction was particularly prominent, with an annual consumption of over 6.5 million tons. Whether it is anti-collision guardrails of expressways, bridge expansion joints, or steel meshes for subgrade reinforcement, they all generated continuous large-scale demand, making highway construction a veritable major consumer of steel bars.

![1764744797480817.jpg 9.jpg]()

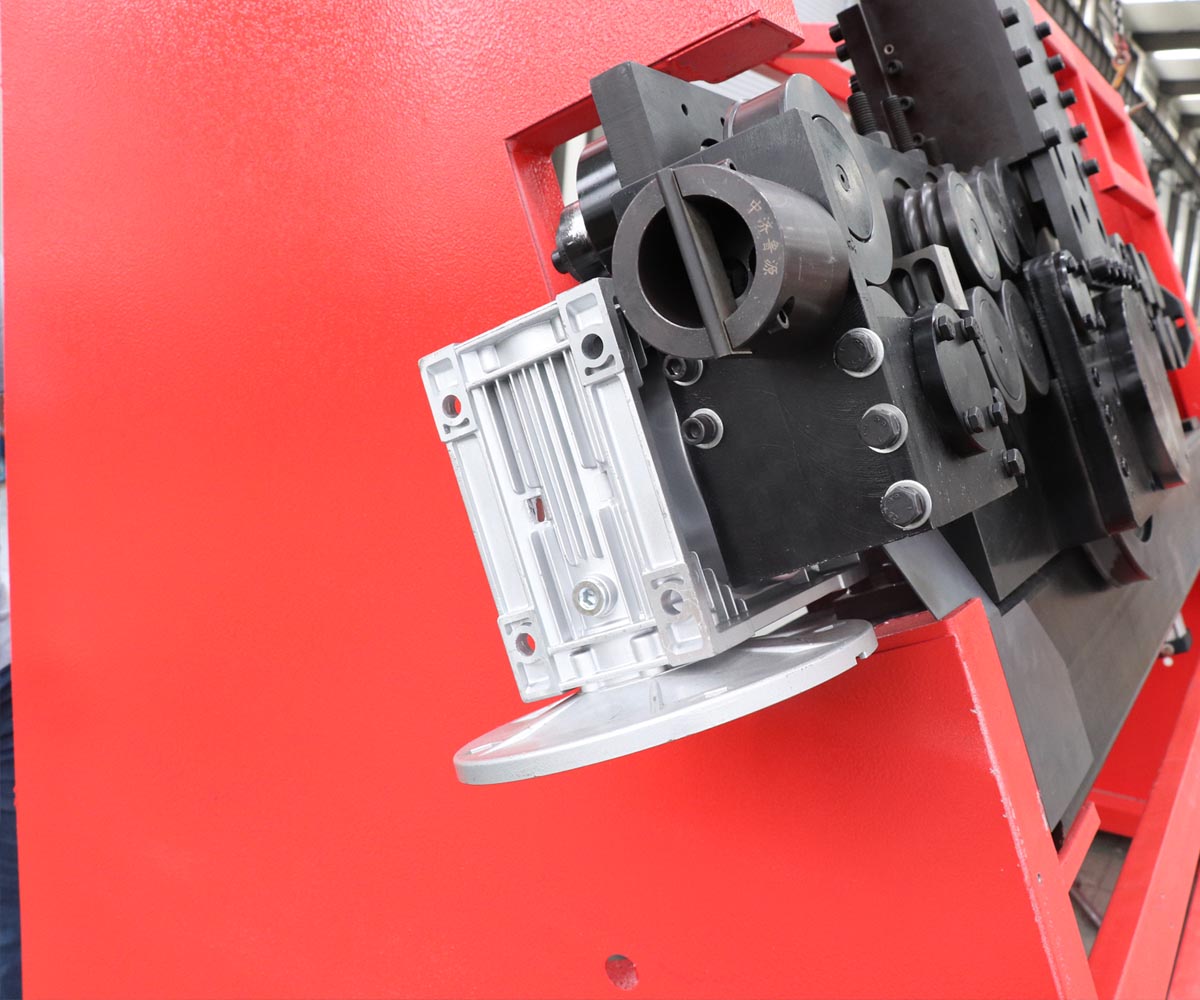

As a key equipment in steel bar processing, the steel bar

bending machine undertakes the core task of shaping steel bars into specified angles and shapes to meet the diverse needs of different engineering structures. It is a practical "shaper" in the construction supply

chain, and its performance directly affects the efficiency of steel bar processing and the quality of finished products. This type of equipment is mainly divided into semi-automatic and fully automatic models, both relying on mature mechanical transmission systems and intelligent control modules to complete operations, but with different applicable scenarios. Semi-automatic models are suitable for small-batch, multi-specification processing scenarios such as small construction sites, with flexible operation and low investment cost; fully automatic models are oriented to large-scale processing scenarios such as prefabricated component factories and steel bar processing centers, realizing continuous and efficient production.

Compared with traditional manual bending or old-fashioned equipment, modern steel bar bending machines have obvious comprehensive advantages. In terms of stability, the optimized mechanical structure and precision parts reduce the failure rate to less than 3% per year; in terms of efficiency, the fully automatic model can complete 15-20 bending operations per minute, which is 3-5 times that of manual operation; in terms of energy conservation and environmental protection, the adoption of servo drive technology reduces energy consumption by 25% compared with traditional models, and the noise during operation is controlled below 75 decibels, and the vibration amplitude is small, effectively improving the workshop environment. In addition, the equipment is equipped with a humanized operation interface—most models adopt a 7-inch color touch screen, supporting graphical parameter input and real-time operation prompts, and the processing precision can reach ±0.5°, ensuring the consistency of finished products.

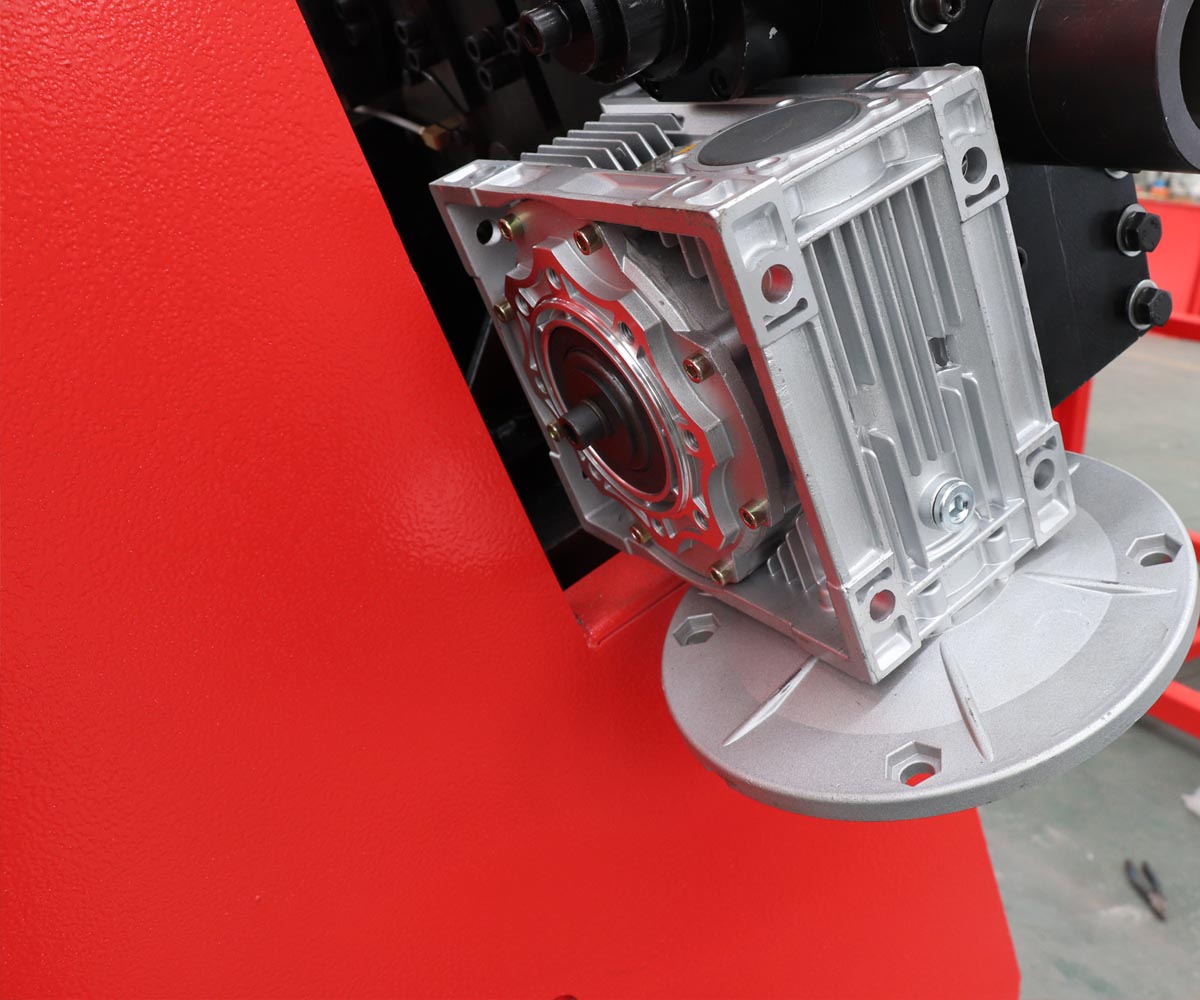

The application scope of steel bar bending machines covers almost all fields of construction engineering, including railways (processing of sleeper steel bars and tunnel support steel bars), highways (bending of guardrail steel bars and bridge pier steel bars), bridges (shaping of beam body stirrups), airports (processing of runway foundation steel meshes), housing construction (forming of column and beam stirrups), as well as professional steel bar processing plants. Especially the automatic CNC

steel bar bending machine independently developed by our company, which integrates the digestion and absorption of advanced European technology and independent intellectual property rights, has realized the integration of straightening, sizing, bending and shearing functions. It breaks the limitation of single-function equipment, realizing "one machine with multiple uses" and greatly saving workshop space and equipment investment costs.

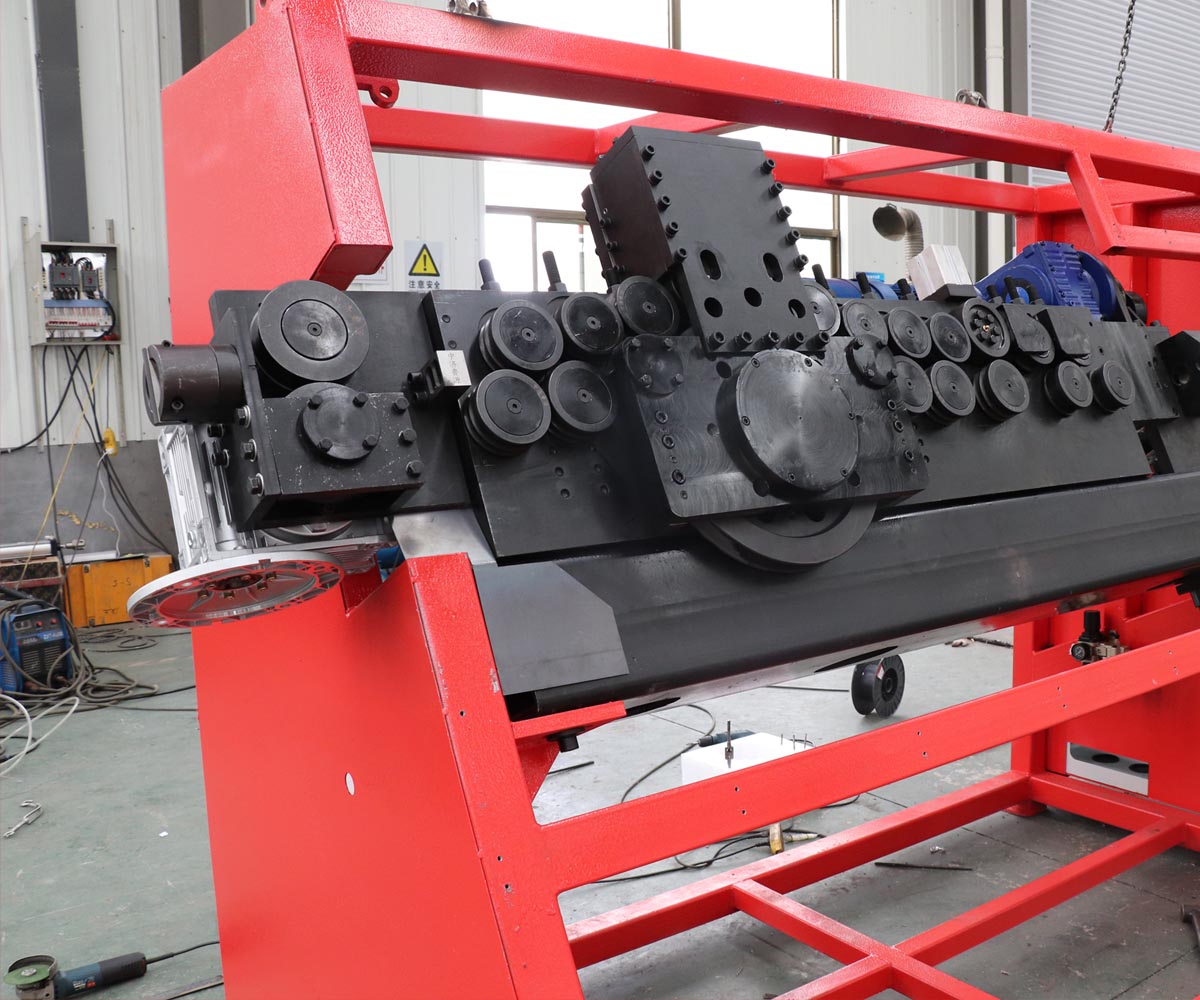

The core feature of this

CNC steel bar bending machine lies in its digital intelligent control system. It adopts digital program control and a man-machine interactive operation interface, which can independently and efficiently complete multiple processes such as piercing, straightening and bending of various graphics (such as square stirrups, rectangular hooks, polygonal shaped bars) with one key. The system can store up to 100 sets of processing parameters, realizing quick switching between different specifications of products and adapting to the needs of multi-batch and small-batch production. In terms of after-sales support, we provide customized accessories service—according to the special processing needs of customers, we can customize bending molds of different specifications and special transmission parts to meet the diverse market demands. At the same time, the modular design of the equipment makes maintenance more convenient—key parts can be quickly disassembled and replaced, reducing downtime loss.