CNC Steel Cage Rolling Machine for Bridge and High-Speed Railway Infrastructure Projects – 5x Production Capacity Increase

Efficient Automated Production: Equipped with a dual main reinforcement fixing mechanism and an automatic spiral reinforcement feeding system, a single machine can produce 8-12 sections of steel cages (with a diameter of 1.2-2.5m) per day on average. This represents a more than 5-fold increase in efficiency compared to manual processing, significantly shortening the project construction period.

Upgraded Precision Control: Adopting a servo motor drive and a PLC (Programmable Logic Controller) numerical control system, the error of main reinforcement spacing is controlled within ±2mm, and the spiral reinforcement pitch precision is ≤±3mm. It fully complies with the GB/T 1499.2-2018 Standard for Steel for Reinforced Concrete.

Intelligent Safety Protection: Equipped with infrared induction anti-pinch devices, welding fume purification systems, and emergency stop modules. While ensuring the safety of operators, it reduces the emission of environmental pollutants and meets the requirements of green construction.

Modular Flexible Adaptation: Supports customized processing of steel cages with a diameter of 500-3000mm and a length of 2-12m. Production specifications can be quickly switched by replacing molds, adapting to multi-scenario needs such as bridge pile foundations and pipe gallery supports.

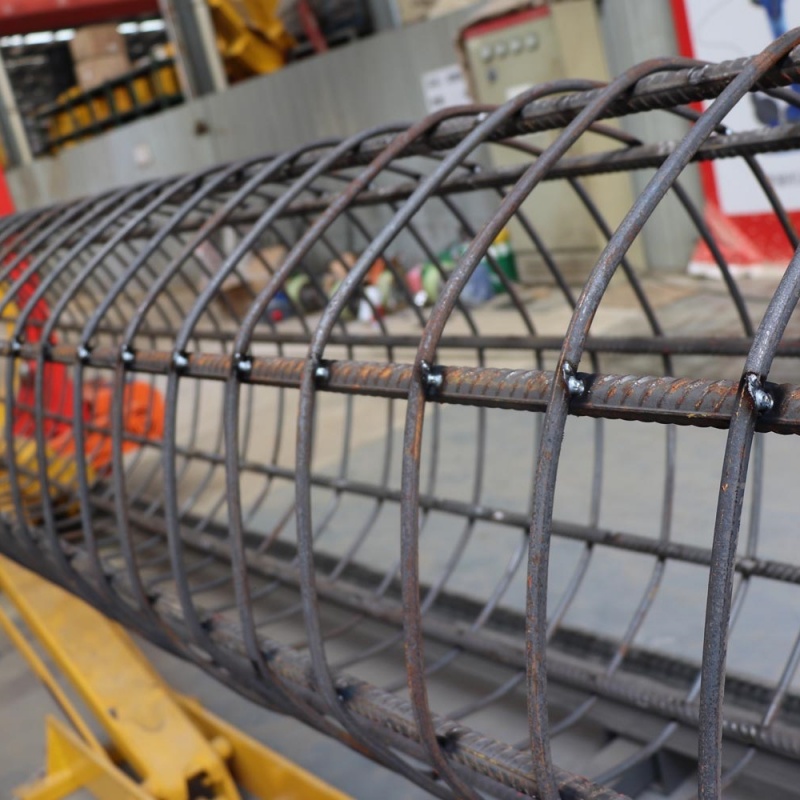

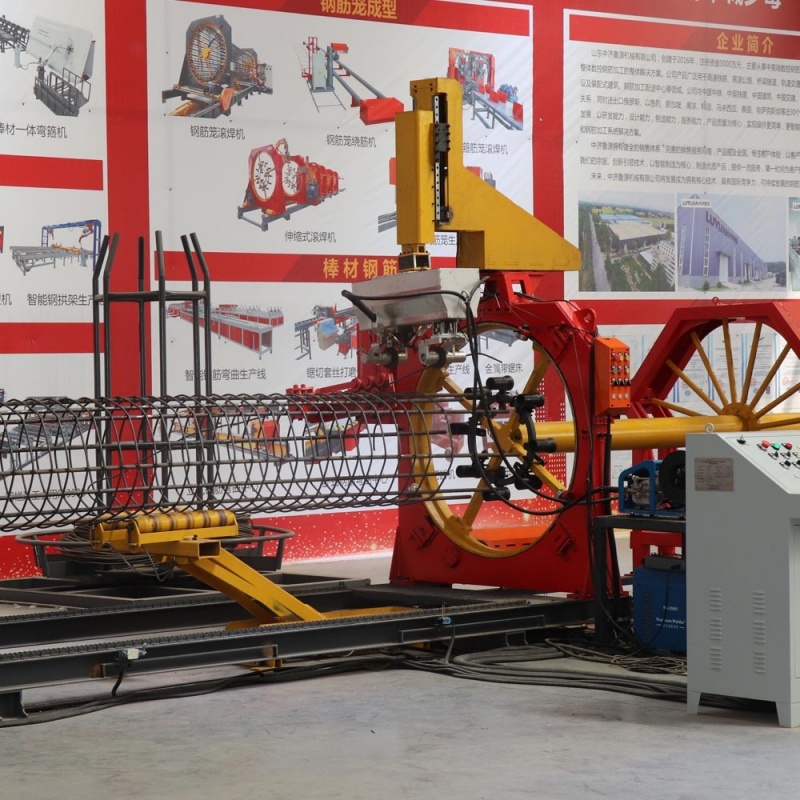

The steel cage rolling machine is an automated and intelligent equipment designed for processing steel cages in reinforced concrete structures. It achieves standardized production of steel cages by precisely controlling processes such as steel bar winding and welding through a numerical control (NC) system. Different from the traditional manual binding method, this equipment integrates core technologies including mechanical transmission, automatic welding, and intelligent control. It is widely used in large-scale infrastructure projects such as bridges, high-speed railways, subways, and pipe piles, completely addressing the industry pain points of low processing efficiency, poor precision, and high labor intensity in steel cage manufacturing.

Efficient Automated Production: Equipped with a dual main reinforcement fixing mechanism and an automatic spiral reinforcement feeding system, a single machine can produce 8-12 sections of steel cages (with a diameter of 1.2-2.5m) per day on average. This represents a more than 5-fold increase in efficiency compared to manual processing, significantly shortening the project construction period.

Upgraded Precision Control: Adopting a servo motor drive and a PLC (Programmable Logic Controller) numerical control system, the error of main reinforcement spacing is controlled within ±2mm, and the spiral reinforcement pitch precision is ≤±3mm. It fully complies with the GB/T 1499.2-2018 Standard for Steel for Reinforced Concrete.

Intelligent Safety Protection: Equipped with infrared induction anti-pinch devices, welding fume purification systems, and emergency stop modules. While ensuring the safety of operators, it reduces the emission of environmental pollutants and meets the requirements of green construction.

Modular Flexible Adaptation: Supports customized processing of steel cages with a diameter of 500-3000mm and a length of 2-12m. Production specifications can be quickly switched by replacing molds, adapting to multi-scenario needs such as bridge pile foundations and pipe gallery supports.

Technical Indicators | Standard Configuration |

Main Reinforcement Specs | Φ12-Φ40mm HRB400E |

Spiral Reinforcement Specs | Φ6-Φ16mm |

Welding Method | CO₂ Gas Shielded Welding |

Motor Power | 15-30kW |

Equipment Weight | 8-15 Tons |

Control Method | Touch Screen + PLC NC System |

Infrastructure Engineering Field: In large-scale projects such as cross-sea bridges and high-speed railway tunnels, it solves the problem of processing high-grade steel bars and ensures the stability of pile foundation structures.

Prefabricated Construction: Adapts to the standardized production of prefabricated pipe piles and prefabricated components, contributing to the upgrading of construction industrialization.

Municipal Engineering: Meets the efficient construction needs of urban rail transit, underground comprehensive pipe galleries, and other projects, reducing on-site operation intensity.

Prioritize manufacturers with ISO9001 quality management system certification and core patented technologies to ensure equipment stability.

Pay attention to the after-sales response capability of the equipment, including installation and commissioning, operator training, and supply of wearing parts.

Conduct regular equipment maintenance, focusing on inspecting key components such as welding electrodes and transmission gears to extend service life.