![small rebar cage machine small rebar cage machine]()

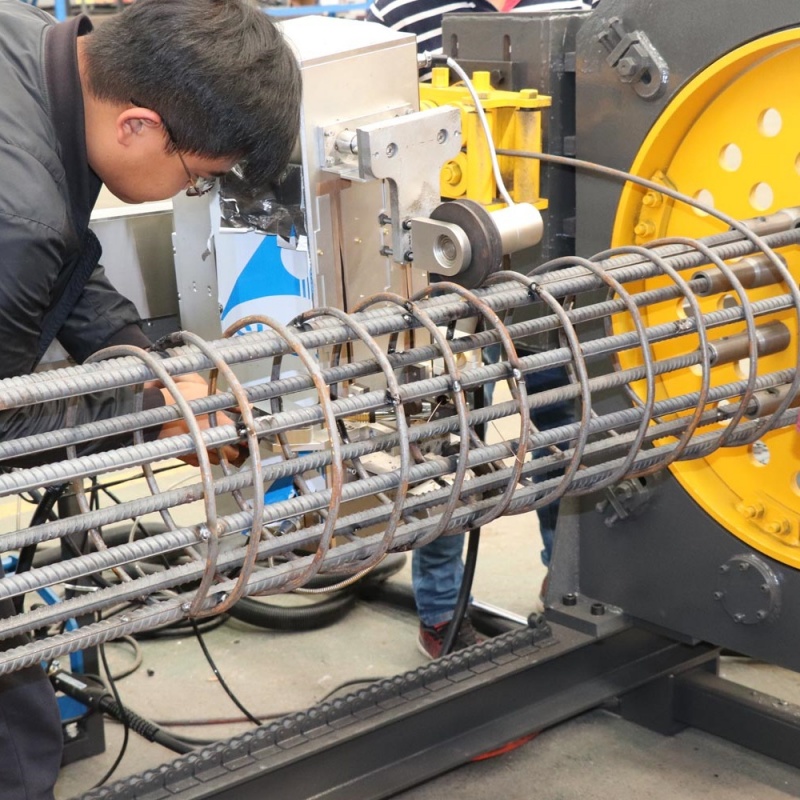

Starting from the entire processing workflow, the LYGH-800 achieves multi-dimensional breakthroughs through technological innovation, completely breaking free from the limitations of traditional processing methods.

The equipment adopts a "dual-spindle synchronous drive + automatic feeding system" and is equipped with a high-precision servo motor, enabling integrated operations of automatic rebar feeding, positioning, welding, and cutting, with no manual intervention required in core processes.

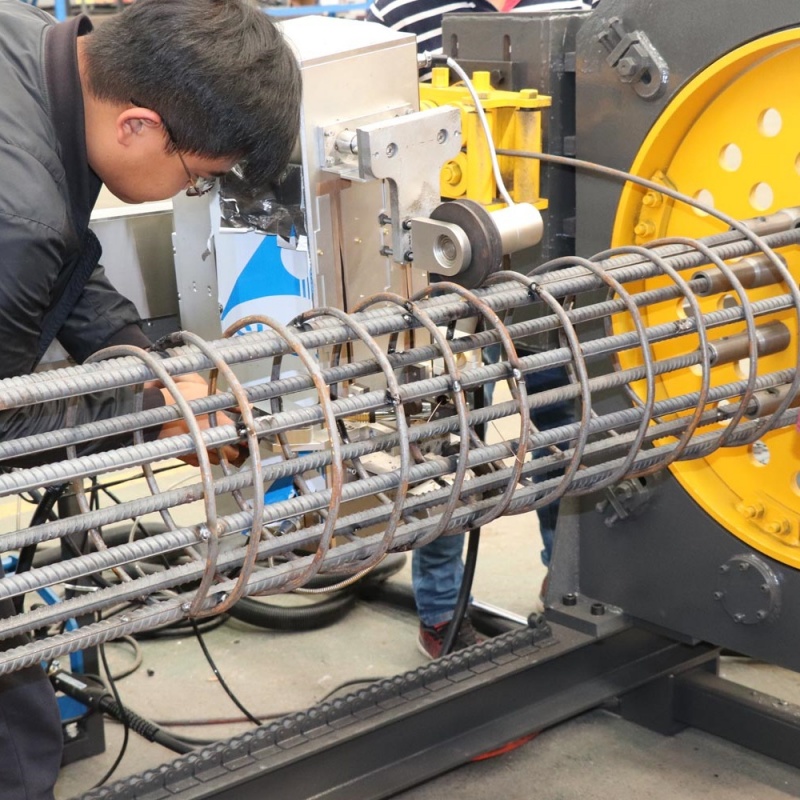

Traditional processing: A rebar cage with a diameter of 2 meters and a length of 12 meters requires 8-10 workers to operate continuously for 12 hours, and only 1-2 sets can be processed per day;

LYGH-800 processing: Only 3 personnel (1 main operator + 2 auxiliary feeding workers) are needed to complete 1 set in 4 hours, and 4-5 sets can be processed per day (based on an 8-hour working system). Efficiency is directly increased by 6-8 times, and labor costs are reduced by more than 60%.

Equipped with an industrial-grade numerical control system, it supports digital programming to set parameters such as rebar spacing and welding point positions. Combined with a high-definition camera and laser positioning device, it monitors and adjusts the welding status in real time:

The positioning accuracy reaches ±1mm, far exceeding the ±5mm error standard of traditional manual work, ensuring the fit between the rebar cage and the pile foundation hole without the need for secondary adjustments;

It automatically matches the welding current and speed to ensure that the penetration depth and fillet height of each welding point comply with the GB/T 12470 standard. The welding qualification rate is stably above 99.5%, avoiding potential safety hazards in the engineering structure from the source.

The equipment integrates intelligent and safety designs to balance high efficiency and risk control:

IoT module: Supports remote monitoring of equipment operation status, processing progress, and consumable usage through a mobile APP/computer background. It automatically alarms and pushes fault solutions when abnormalities occur, reducing downtime by 40%;

Safety protection: Equipped with infrared safety light curtains, emergency stop buttons, and fully enclosed guardrails. The equipment automatically stops when operators approach dangerous areas, achieving zero risk of mechanical injury.

Adopting a modular structure design, the core components have strong universality, allowing daily maintenance to be completed without professional personnel. At the same time, the equipment's energy consumption is optimized, saving 15% more electricity than similar equipment. The later maintenance cost is 30% lower than the industry average, resulting in significant cost-effectiveness for long-term use.

![rebar cage machine rebar cage machine]()

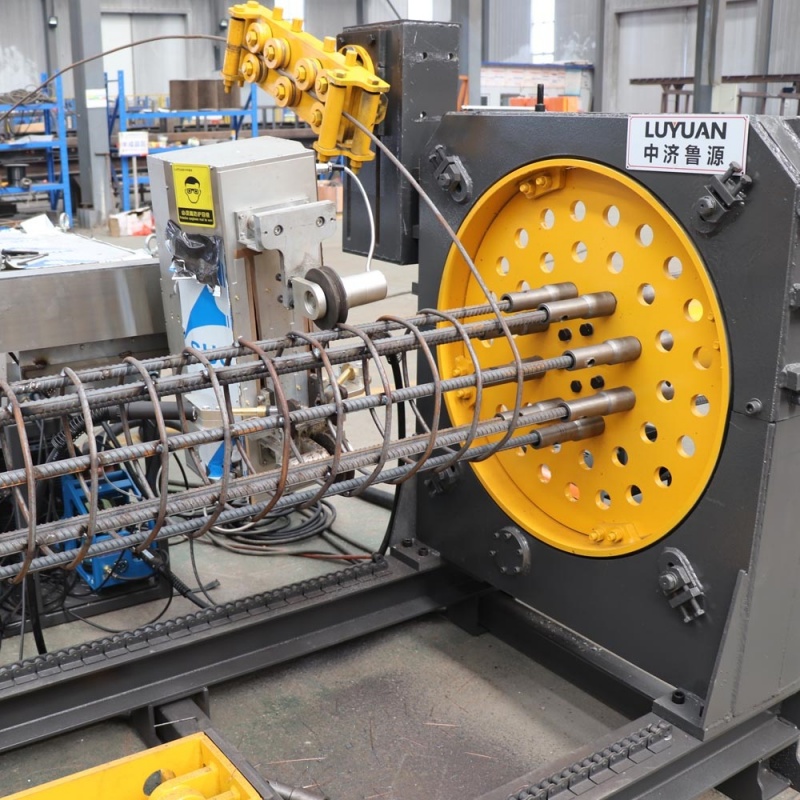

The processing range and performance parameters of the LYGH-800 can cover the rebar cage processing needs of most infrastructure projects, with specific specifications as follows:

With its flexible processing adjustment capability, the LYGH-800 can adapt to the rebar cage processing needs of different infrastructure scenarios, enabling rapid specification switching without replacing core components:

Bridge Engineering: Processing of rebar cages for highway/railway bridge pile foundations, adapting to pile foundation designs of different diameters;

Underground Engineering: Rebar cages for supporting structures of subway tunnels and comprehensive pipe corridors, meeting the requirements of long-length and high-precision processing;

High-Rise Buildings: Rebar cages for cast-in-place piles in super high-rise building foundations, ensuring precise matching with the foundation structure;

Water Conservancy Engineering: Rebar cages for the foundations of reservoir dams and water transmission pipelines, adapting to complex outdoor operating environments.

To ensure the efficient operation of the equipment, Shandong Zhongji Luyuan Machinery provides full-cycle services for the LYGH-800:

Customized Solutions: Adjust equipment processing parameters according to project needs and provide exclusive production process design;

On-Site Commissioning: Arrange engineers to conduct on-site installation and commissioning after equipment delivery to ensure immediate production;

Training Support: Provide special training for operators on numerical control systems, safe operation, and daily maintenance;

After-Sales Response: 24/7 online after-sales service, with rapid response to fault diagnosis and component replacement to ensure project progress.

Through technological innovation, the LYGH-800

Rebar Cage Rolling Machine has transformed rebar cage processing from "manual dependence" to "intelligence-driven". It not only improves the construction efficiency and quality of individual projects but also promotes the standardization and intelligent upgrading of the processing link in the infrastructure industry, making it a core equipment for cost reduction and efficiency improvement in modern infrastructure projects.

Would you like me to organize a parameter comparison table for the LYGH-800 Rebar Cage Rolling Machine? It can intuitively compare its key indicators with those of traditional equipment and similar competing products, making it easier for you to demonstrate the equipment's advantages to customers or your team.