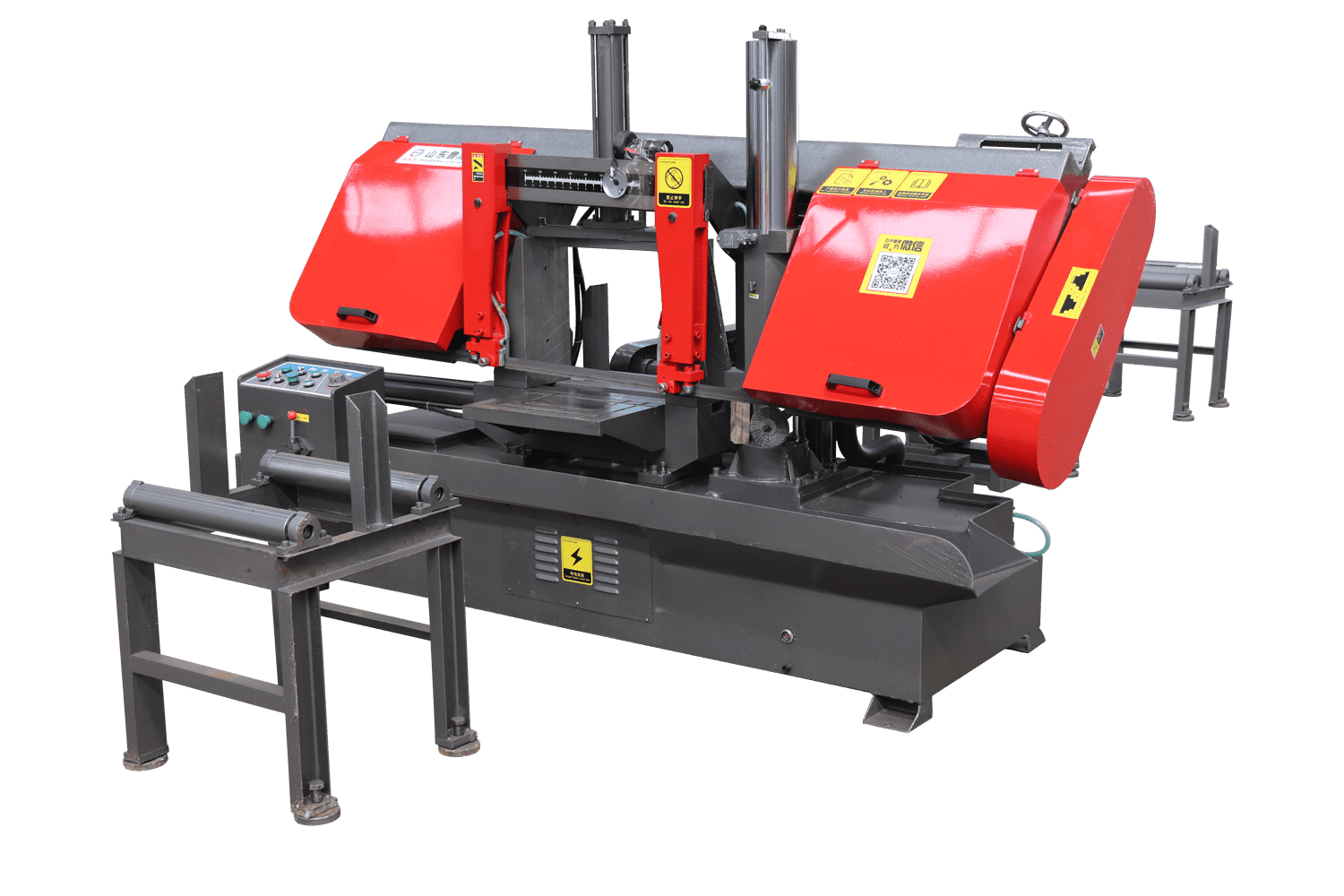

Steel Bar Cutting Machine Production Line

1. High precision and stability

Numerical control system control: By programming the cutting length and quantity, manual measurement errors are eliminated to ensure cutting accuracy (usually with an error of st1mm)

Automated operation: reduces human intervention, avoids deviations caused by fatigue or improper operation, and is suitable for large-scale standardized operations.

2. Significant improvement in production efficiency

High speed cutting: It can cut dozens of times per minute, far higher than traditional manual or semi-automatic equipment.

Continuous operation: supports long-term operation, combined with an automatic feeding system, greatly shortens the steel bar processing cycle.

Batch processing: Multiple length specifications can be preset, quickly switch production tasks, and adapt to the needs of multiple varieties.

3. Outstanding safety performance

Fully enclosed protection: using safety doors, infrared sensors, and other devices to prevent operators from coming into contact with the cutting area.

Automatic warning function: The fault detection system can give real-time alarms and shut down, reducing the risk of accidents.

Compliant with industrial safety standards: significantly reduces the probability of work-related injuries compared to traditional shearing equipment.

4. Multi functionality and strong adaptability

Multi specification compatibility: can handle steel bars with different diameters (such as 46-440mm) and materials (threaded steel, round steel, etc.).

Customized programming: supports complex machining requirements (such as cutting to length and multi segment combination cutting).

Strong environmental adaptability: Some models can operate stably under harsh conditions such as high dust and humidity.

Product Description

CNC rebar shearline rebar cutting tool

Engineered for efficiency, precision, and ease of operation, the Automatic Concrete Steel Cage Welding Machine brings next-level automation to steel cage fabrication for concrete reinforcement. Below are its core advantages:

1.High degree of automation greatly reduces labor intensity.

2.Good lubrication performance of main engine head,adopte the distributed oil filling system.

3.The whole machine is equipped with horizontal feeding device for easy feeding.

4. Adopt scissor blade design, cut off the material deformation amount is small.

5. Processing incoming/outgoing stock rack, can process more than one steel bar at a time.

6.The machine adopts 3 positioning baffles to fix the ruler, which is simple and accurate, and can fix the ruler of any length.

Specification

Details Images

Our Company

Customer Photos

Recommend Products

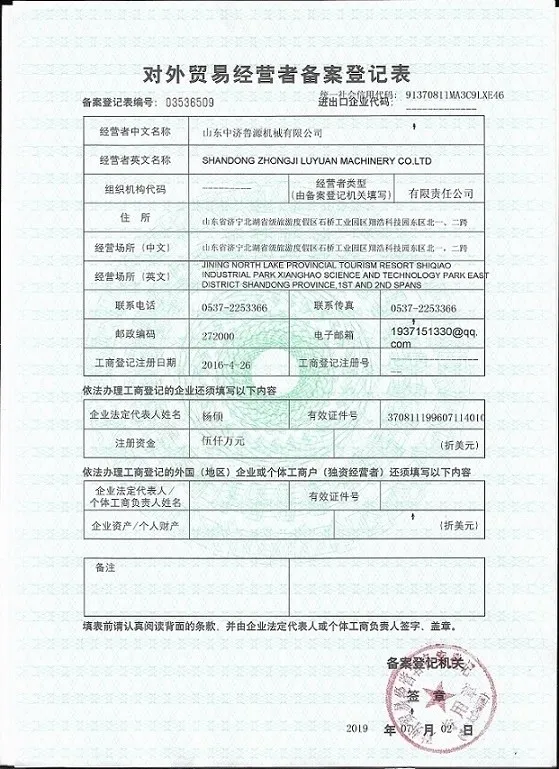

Certifications