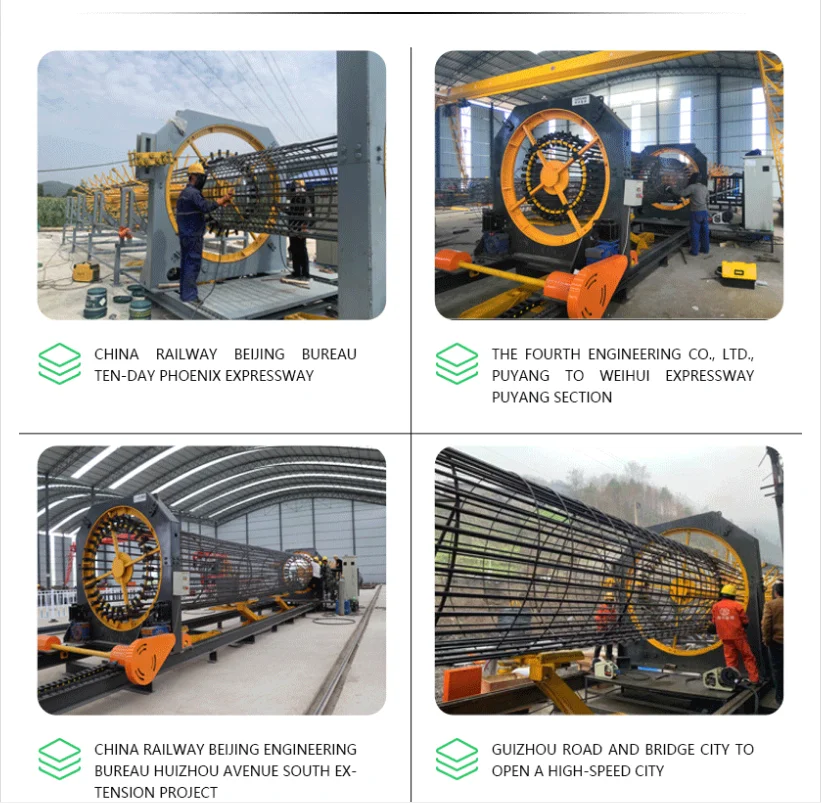

1650mm Telescopic Steel Cage Roll Welding Machine

1. control system: PLC, touch screen, inverter.

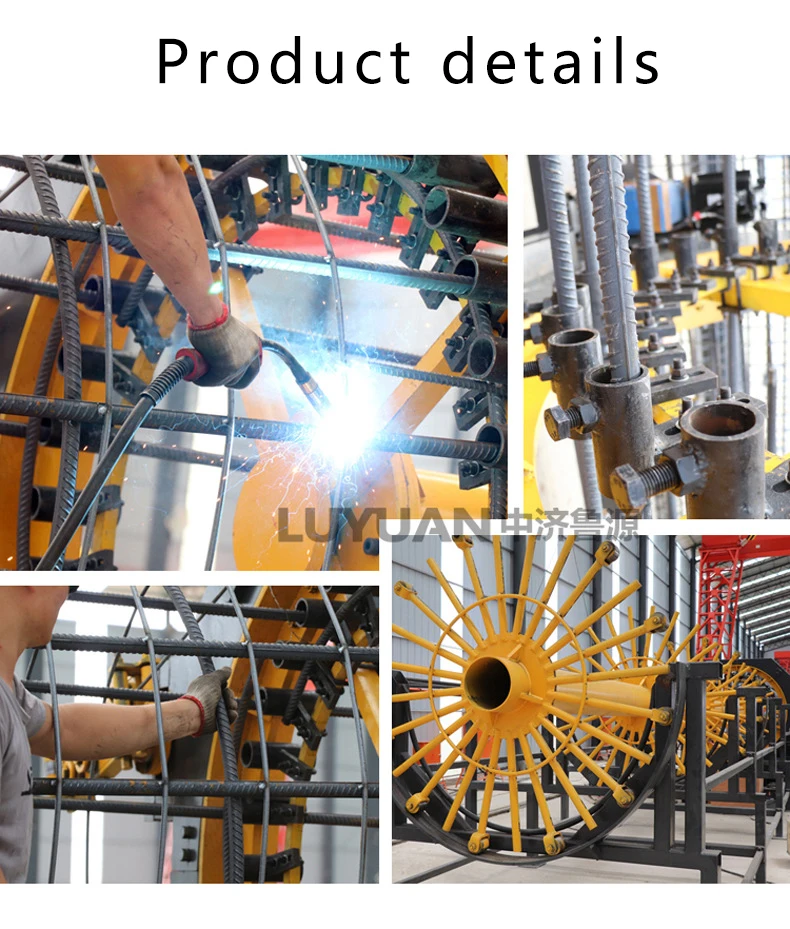

2. automatic wire feeding mechanism, the spacing can be adjusted online, the error is small, high molding quality.

3. frequency control drag cage institutions, high running accuracy.

4. with more automatic hydraulic feed rollers, to prevent steel cage deformation due to its own weight.

5. equipped with automatic feeding device, easy to operate and improve efficiency.

6. template using the template ring plus catheter combination, can be quickly replaced and transform the quantity of main steel cage wire .

7. straightening systems are made of high strength alloy material, high strength, anti-wear and improve the life of wearing parts

Incorporating an advanced PLC control system, intuitive touch screen interface, and high-performance inverter, the intelligent control core enables precise automation of welding processes. The PLC system allows for accurate parameter setting, ensuring every operation adheres to pre-defined standards for consistent quality. The user-friendly touch screen simplifies parameter adjustment and program selection, reducing operational complexity. The inverter dynamically controls motor speed based on production needs, optimizing energy efficiency without compromising welding precision. This stable and efficient control system is the cornerstone of the machine's high-accuracy welding capabilities, making the 1650mm telescopic steel cage roll welding machine a standout choice in the industry.

Crafted from high-strength alloy materials, the straightening systems offer superior durability and wear resistance, extending the service life of consumable parts. During steel bar straightening, they precisely eliminate bends and deformations, ensuring materials enter the welding process in perfect straightness—laying a solid foundation for subsequent quality. The high-strength alloy construction withstands long-term heavy loads, minimizing maintenance costs and downtime for stable, reliable production.

1. According to your requirements to help you design a reasonable solution,choose a reasonable equipment .

Sale Service

1. Provide the video to help you to learn about how the device works.

2.Help you to know the details of the Key parts and our advantage.

After-sales Service

1. Guarantee for One year.

2. Quality problem, we will send you the accessories.

3. Free repair whole using life (without the freight and accessories charge)

4.24 hours maintenance response: timely feedback within 24 hours after acceptance of maintenance service.

5. Customer can enjoy lifelong value maintenance.

6. Professional and international experienced after-sales service team.