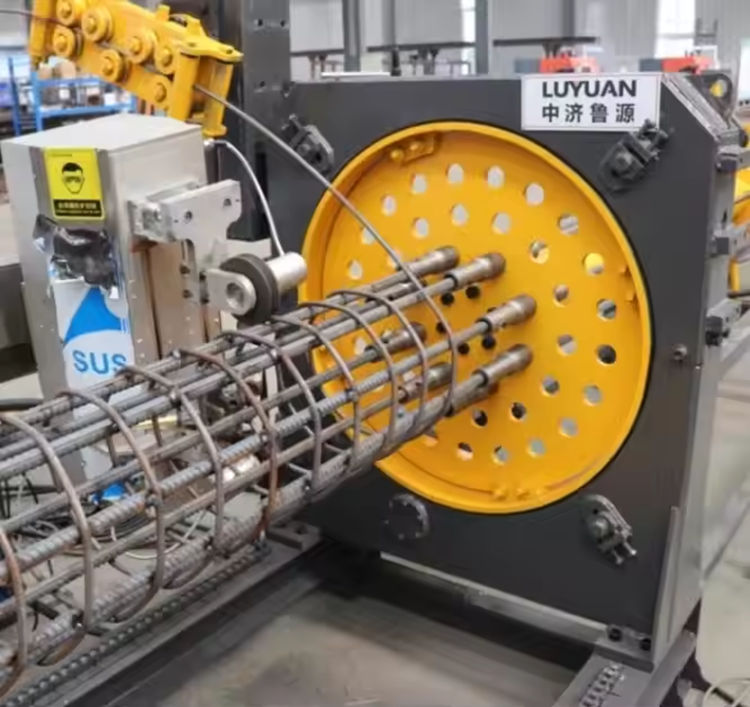

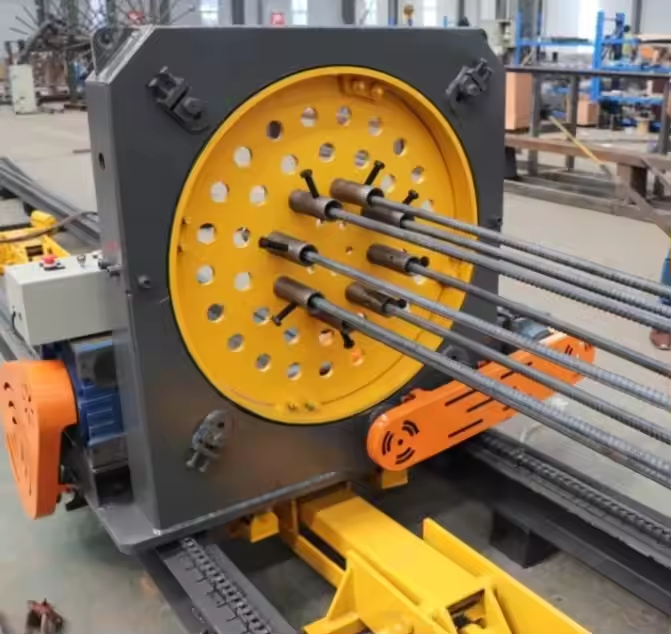

800mm Steel Cage Rolling Welding Machine

1. control system: PLC, touch screen, inverter.

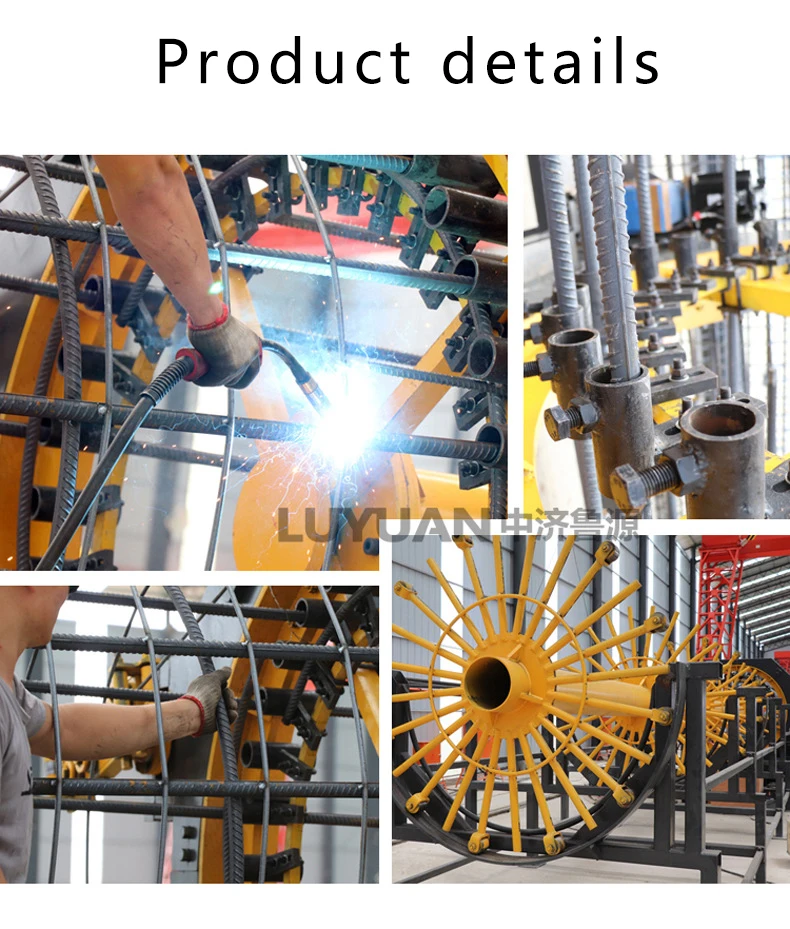

2. automatic wire feeding mechanism, the spacing can be adjusted online, the error is small, high molding quality.

3. frequency control drag cage institutions, high running accuracy.

4. with more automatic hydraulic feed rollers, to prevent steel cage deformation due to its own weight.

5. equipped with automatic feeding device, easy to operate and improve efficiency.

6. template using the template ring plus catheter combination, can be quickly replaced and transform the quantity of main steel cage wire .

7. straightening systems are made of high strength alloy material, high strength, anti-wear and improve the life of wearing parts

800mm Steel Cage Rolling Welding Machine

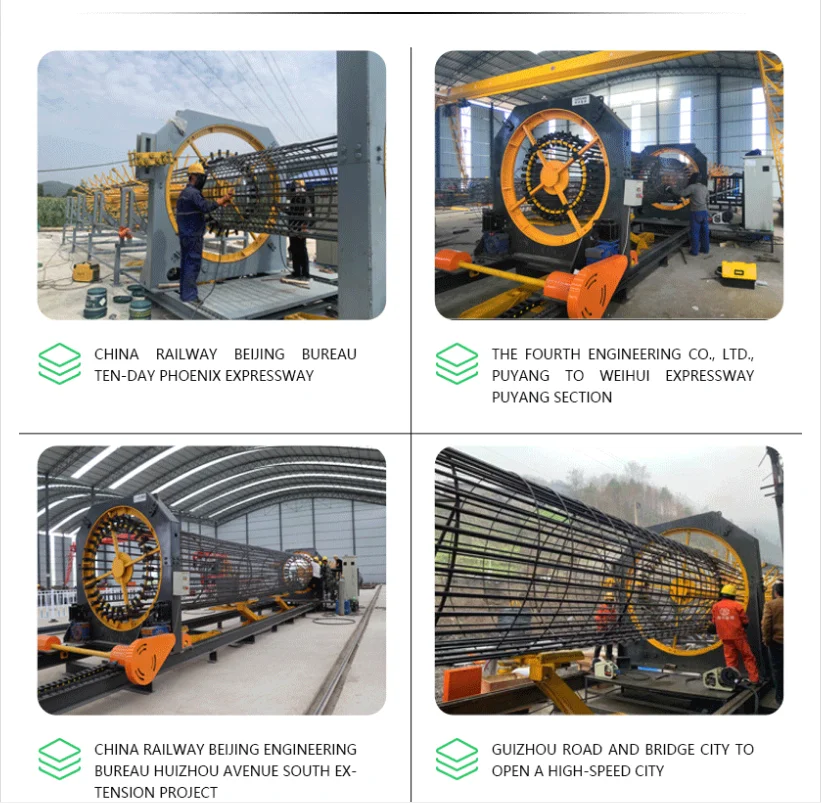

Engineer high-strength, precision steel cages for infrastructure projects with our 800mm Steel Cage Rolling Welding Machine—a robust, automated solution designed for efficiency, durability, and ease of operation. Ideal for highway, railway, and civil engineering applications, this machine combines advanced PLC control, adaptive feeding mechanisms, and wear-resistant components to deliver consistent, high-quality cage fabrication.

Core Features for Automated Cage Production

Technical Specifications

Ideal Applications

Why Choose Our Rolling Welding Machine?

Quality Assurance

Upgrade your steel cage production with the 800mm Steel Cage Rolling Welding Machine—where automation, precision, and durability converge to build the foundation of tomorrow’s infrastructure. Contact us today to discuss how this machine can streamline your fabrication process.

1. According to your requirements to help you design a reasonable solution,choose a reasonable equipment .

Sale Service

1. Provide the video to help you to learn about how the device works.

2.Help you to know the details of the Key parts and our advantage.

After-sales Service

1. Guarantee for One year.

2. Quality problem, we will send you the accessories.

3. Free repair whole using life (without the freight and accessories charge)

4.24 hours maintenance response: timely feedback within 24 hours after acceptance of maintenance service.

5. Customer can enjoy lifelong value maintenance.

6. Professional and international experienced after-sales service team.