Rebar Stirrup Bender Construction Site

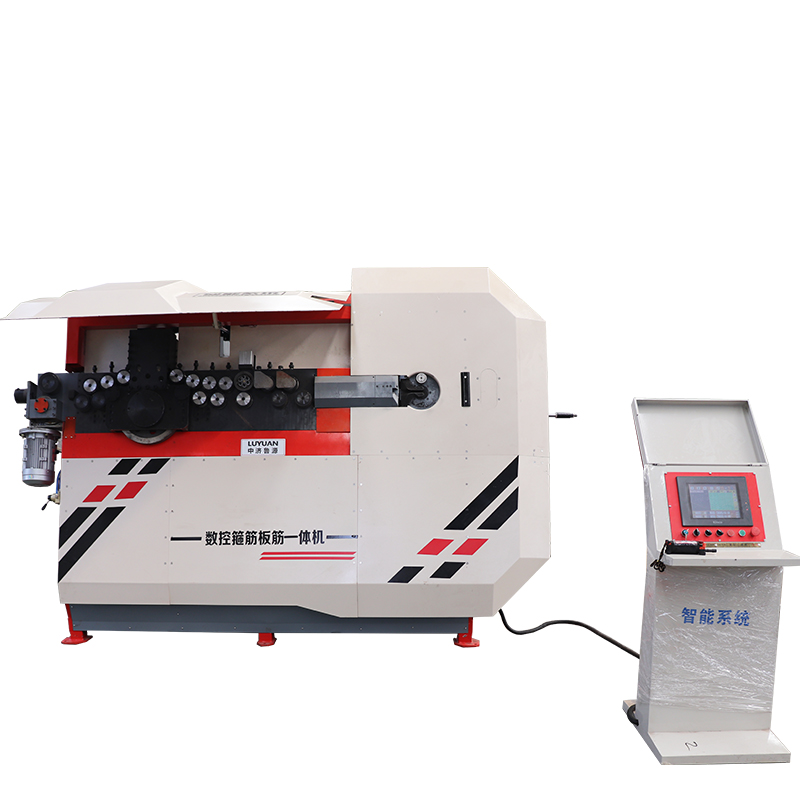

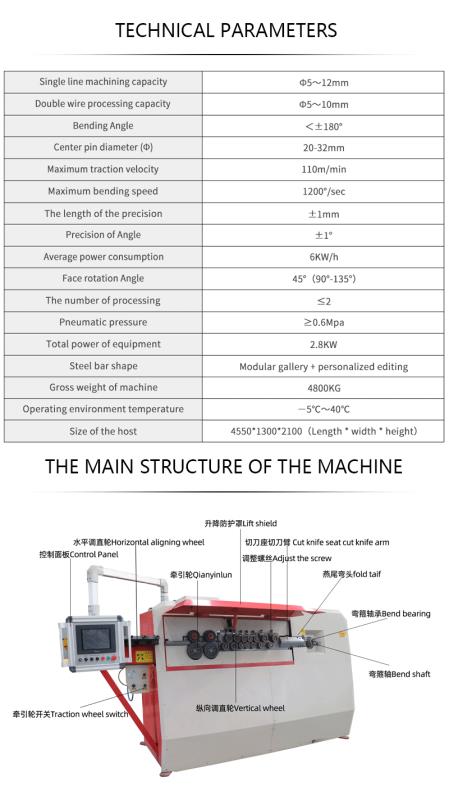

China made luyuan machinery 16mm stirrup bender of wire and bar bending machine hot sale

Features:

1.First, the scope of use: widely used in railways, highways, bridges, airports, housing

construction, steel processing plants and other fields.

2. Function: It is a fully automatic CNC steel bar hoop bending machine, which is suitable for the forming and processing of

stirrups, hook bars and plate bars.

3. Function: 1. Rebar processing wire within 12 specifications. 2, 14 or 16 steel bar for processing.

4. Features: 1. Wire processing adopts curve straightening, which has all the advantages of curve straightening. 2. Automatic

step feeding is adopted for bar processing (magnetic feeding to be developed).

Rebar Stirrup Bender for Construction Sites

Ladder Feeding System

Engineered for smooth, continuous material handling, the ladder-style conveyor ensures steady, guided feeding of steel bars/wires up to 12mm in diameter.

Adjustable guides and anti-slip rollers minimize misalignment, reducing material waste and setup time—perfect for high-volume production.

Ergonomic height positioning allows operators to load materials effortlessly, even in tight construction site environments.

Hoop Bending Machine Host

The core processing unit integrates advanced servo-driven technology to achieve ±1° angular accuracy and ±2mm dimensional precision, meeting strict structural standards for stirrup fabrication.

Heavy-duty steel casting ensures stability during high-force bending, while a user-friendly digital interface lets operators input dimensions directly—no complex programming required.

Quick-change dies support multiple stirrup shapes (rectangular, circular, U-shaped) and sizes, adapting to diverse project requirements in seconds.

Handles both cold-rolled steel wires (4–8mm) and deformed bars (6–12mm), making it suitable for reinforcing columns, beams, slabs, and precast elements.

Automated cutting and bending cycles reduce manual intervention, cutting labor costs by 30% compared to traditional manual methods.

On-board error detection flags misfeeds or dimension discrepancies in real time, ensuring zero-defect output and minimal rework.

Weather-resistant coating and IP54-rated electrical components protect against dust, moisture, and vibrations—ideal for outdoor use.

Compact footprint (1.8m x 0.9m x 1.2m) fits through standard construction gates and works efficiently in confined spaces.

Low-maintenance design with self-lubricating components and easy-access service panels, minimizing downtime during peak project phases.

Time Savings: Process up to 500 stirrups per hour with consistent quality, accelerating project timelines.

Cost Efficiency: Single machine replaces multiple tools, reducing equipment investment and storage needs.

Precision Assurance: Engineered for compliance with ISO, ASTM, and GB standards, ensuring structural integrity in every bend.

Operator Friendly: intuitive controls require minimal training, empowering your team to start production quickly.

Residential buildings (column stirrups, slab reinforcement)

Commercial complexes (foundation hoops, beam reinforcements)

Infrastructure projects (bridge piers, tunnel linings, culverts)

Precast concrete factories (modular component fabrication)

1, warranty period 1 year from B/L date.

2, within warranty period you could get spare parts for free.

3, You could get free training in our factory.

4, 24 hours technical support by Email, calling or door-to-door service.

we are manufacturer of pile cage welding machine , CNC automatic steel bar bending machine,bending machine ,cutting machine, steel bar straightening machine etc.we also can supply setting up a new factory full line service . We have already exported various kinds of concrete pile ,pole and pipe concern making machines to overseas countries and regions such as Indonesia, Parkistan, Vietnam, Myanmar ,Korea,Malaysia ,South african,Mideast Southeastern Asia, etc..

Team

Our Team

Team

Our Team