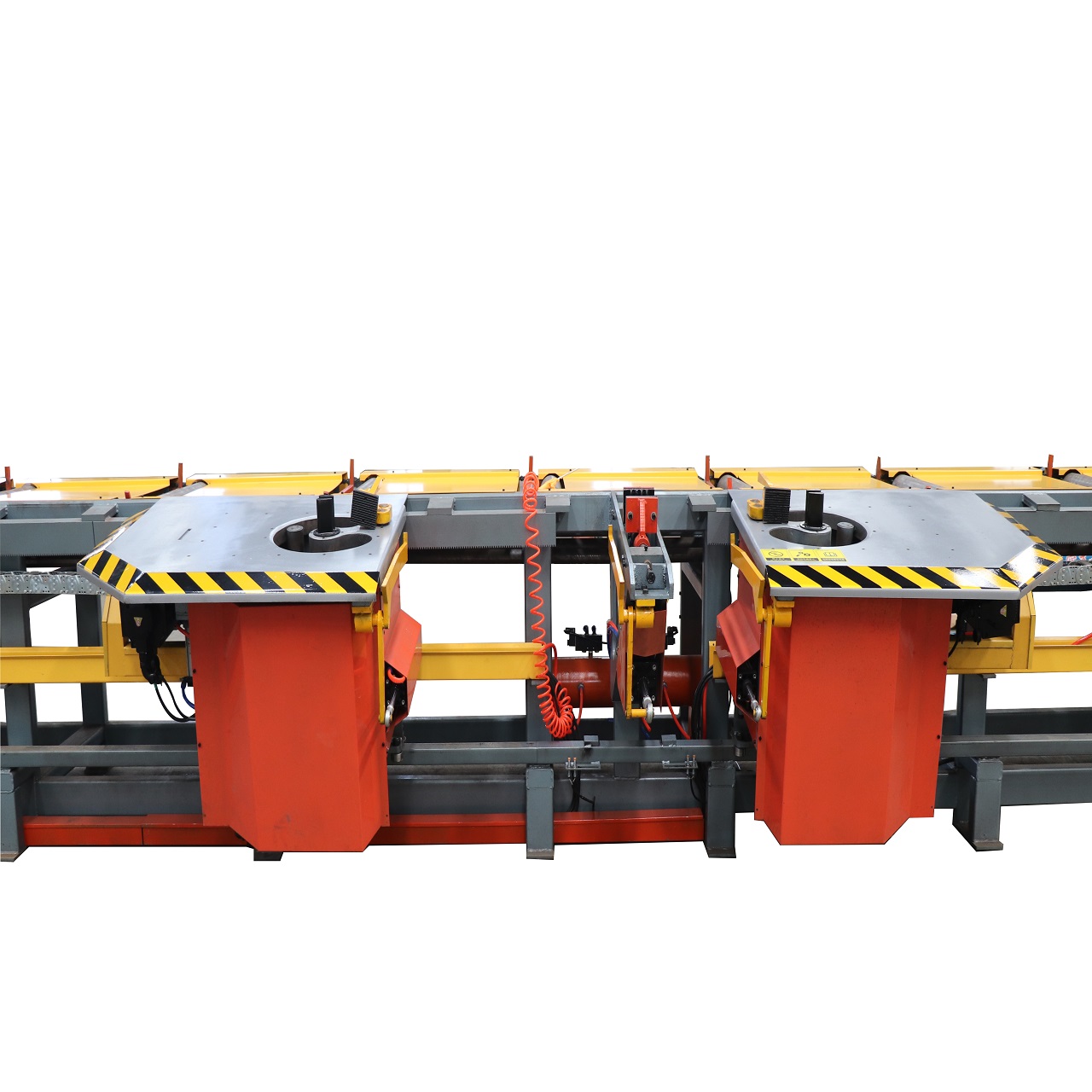

6-32mm Automatic Rebar Bending Line

LYWQ-32 two head vertical CNC bending center

Features

1. Brake lock mechanism ado: pts 8 pneumatic brakes to ensure the forming accuracy. 2. The control system adopts high-performance imported PLC and hd touch screen, which is convenient to operate and responsive. 3. The bending mold and the bending axle sleeve are made of special steel and heat-treated with high wear resistance and long service life. 4. The walking track adopts high-precision rack and gear transmission with low noise. 5. Double independent nose, more efficient work, free fixed ruler, details of patent modification. 6. Rolling feeding platform, can carry a large number of raw materials, convenient loading and unloading.

6-32mm Automatic Rebar Bending LineProduct Display

Engineer high-precision rebar structures with our 6-32mm Automatic Rebar Bending Line—a cutting-edge solution designed for construction sites, precast plants, and steel fabrication shops. This fully automated bending system combines advanced technology, durable components, and user-friendly controls to deliver unmatched efficiency and accuracy for rebars ranging from 6mm to 32mm in diameter.

Features 8 high-response pneumatic brakes in the brake lock mechanism, ensuring zero positional deviation during bending for ±1° angular accuracy and consistent forming quality.

Ideal for complex shapes (stirrups, hoops, hooks) in seismic-resistant structures and high-rise buildings.

Powered by an imported high-performance PLC system and HD touchscreen interface, enabling intuitive programming of bending angles, lengths, and quantities.

Real-time parameter adjustment and recipe storage for up to 50 custom projects, reducing setup time by 40% compared to manual systems.

Heat-treated special steel bending molds and axle sleeves resist deformation and abrasion, maintaining precision over 10,000+ bending cycles—perfect for 24/7 heavy-duty operations.

Minimal maintenance required, with replaceable components designed for quick swap-outs (15 minutes or less).

Utilizes a high-precision rack and pinion drive system for smooth, low-noise (≤75dB) operation, ensuring stable movement and long-term reliability.

Reduces mechanical wear by 30% compared to chain-driven systems, enhancing overall machine lifespan.

Dual-nose design enables simultaneous bending of two rebars, doubling productivity (up to 200 bends/hour) while maintaining free-fixed ruler flexibility for mixed-size projects.

Patent-modified details optimize rebar positioning, eliminating material jams and improving workflow continuity.

Integrated rolling feeding platform accommodates up to 2 tons of raw materials, minimizing frequent loading/unloading and supporting continuous operation.

Adjustable guides ensure straight, stable feeding of both round and ribbed rebars (HRB400/500, ASTM A615).

The bending center of a steel bar refers to the central axis position of the bent portion of the steel bar during the bending process. Usually, when bending steel bars, the bending center of the steel bar is determined by the bending die (such as the bending wheel on the bending machine). In actual operation, the bending center of the steel bar is usually determined by the diameter of the steel bar, the bending angle, and the bending equipment.

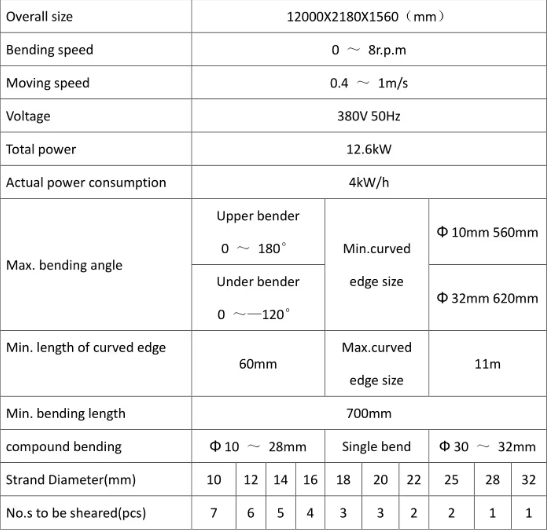

Product Parameters

1, warranty period 1 year from B/L date.

2, within warranty period you could get spare parts for free.

3, You could get free training in our factory.

4, 24 hours technical support by Email, calling or door-to-door service.

we are manufacturer of pile cage welding machine , CNC automatic steel bar bending machine,bending machine ,cutting machine, steel bar straightening machine etc.we also can supply setting up a new factory full line service . We have already exported various kinds of concrete pile ,pole and pipe concern making machines to overseas countries and regions such as Indonesia, Parkistan, Vietnam, Myanmar ,Korea,Malaysia ,South african,Mideast Southeastern Asia, etc..

Team

Our Team

Team

Our Team