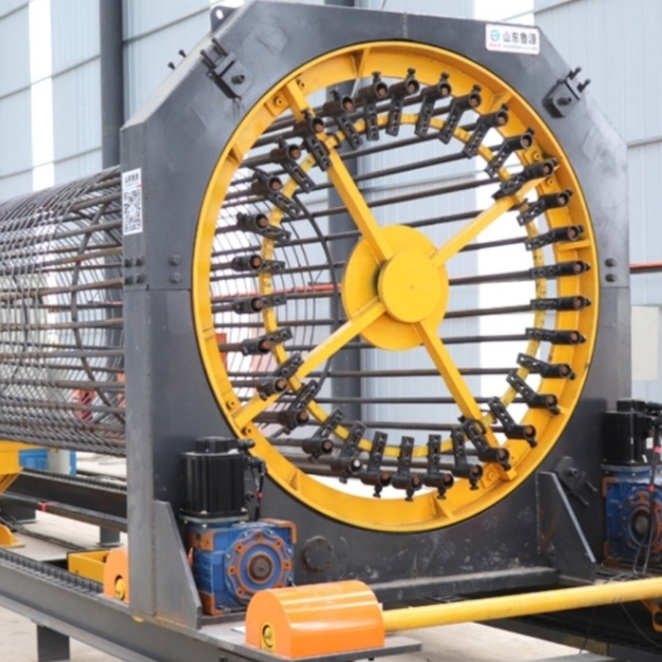

CNC Steel Bar Cage Welding Machine

LYGH-2000

The steel bar cage production equipment controlled by PLC ended the history of manual binding of steel cages. It’s widely used in highway, high-speed railway, rail transit, power engineering, water conservancy projects and other projects. The equipment is mature, stable and easy to operate. Customers can choose the matching double gun automatic welding manipulator.

Cage length: 12m, Customizable

Diameter of main bar of steel cage: Φ16~50

Diameter of winding bar of steel cage: Φ5~16

Welding method of the winding bar: Welding robot or manual

CNC Steel Bar Cage Welding Machine---LYGH2000

Transform rebar cage fabrication with our CNC Steel Bar Cage Welding Machine—a PLC-controlled automated solution that eliminates manual binding, delivering precision, speed, and reliability for large-scale infrastructure projects. Engineered for highway, railway, and civil engineering applications, this machine combines advanced technology with customizable features to meet the demanding needs of modern construction.

Revolutionizing Rebar Cage Production

Say goodbye to time-consuming manual (manual binding) and welcome a new era of efficiency:

Fully Automated PLC Control: Programmable logic controller (PLC) system enables one-click setup for cage length (up to 12m, customizable), main bar diameter (Φ16–50mm), and winding bar specifications (Φ5–16mm)—reducing setup time by 70% compared to traditional methods.

Mature & Stable Performance: Field-proven design with 99.8% uptime, ideal for 24/7 operation in harsh worksite environments like coastal bridges, high-speed railway viaducts, and nuclear power foundations.

Core Advantages for Efficient Fabrication

1. Dual Welding Options for Flexibility

Automatic Welding Manipulator (Optional): Equip with a double-gun robotic arm for fully automated winding bar welding, achieving 360° seamless joins at speeds up to 2m/min—perfect for high-volume production of standardized cages.

Manual Welding Mode: Retains manual welding capability for custom cages or on-site adjustments, offering versatility for mixed-project workflows.

2. Precision Engineering for Structural Integrity

±2mm Positioning Accuracy: Laser-guided main bar alignment and tension-controlled winding ensure uniform spacing and secure welds, meeting strict international standards (ISO 6934, GB/T 1499.3).

Low-Deformation Welding: Robotic welding reduces heat-affected zones, minimizing cage distortion and eliminating the need for post-weld straightening.

3. User-Centric Design for Easy Operation

Intuitive HMI Interface: 15" touchscreen displays real-time production data, error alerts, and program presets—no specialized training required for operators.

Modular Construction: Quick-release components and accessible maintenance points reduce downtime, with average tool changes completed in <10 minutes.

4. Wide Application Across Infrastructure Sectors

Trusted in critical projects worldwide:

Highway & Railway: Pile cages for bridge piers, tunnel linings, and embankment reinforcements.

Power & Water Conservancy: Foundation cages for wind turbines, nuclear reactors, and dam structures.

Urban Transit: Metro station pile foundations and light rail viaduct components.

The steel bar cage production equipment controlled by PLC ended the history of manual binding of steel cages. It’s widely used in highway, high-speed railway, rail transit, power engineering, water conservancy projects and other projects. The equipment is mature, stable and easy to operate. Customers can choose the matching double gun automatic welding manipulator.

Parameters

Model | LYGH-1500 | LYGH-1800 | LYGH-2000 | LYGH-2200 | LYGH-2500 | LYGH-3000 |

Steel cage pile diameter | 500~1500 | 500~1800 | 600~2000 | 600~2200 | 800~2500 | 800~3000 |

Equipment power | 16KW | 18KW | 23KW | 23KW | 25KW | 38KW |

Occupied area(No side automatic welding) | 28m×6m | 28m×6m | 28m×6.5m | 28m×7m | 28m×9m | 28m×11m |

Occupied area(Including side automatic welding) | 28m×8.5m | 28m×8.5m | 28m×9m | 28m×9.5m | 28m×11.5m | 28m×13.5m |

Cage length | 12m, Customizable | |||||

Diameter of main bar of steel cage | Φ16~50 | |||||

Diameter of winding bar of steel cage | Φ5~16 | |||||

Welding method of the winding bar | Welding robot or manual | |||||

Distance between two winding bars | ≤300mm | |||||

Hydraulic pressure | ≤16MPa | |||||

Gas pressure | ≤0.8MPa, Automatic welding gas | |||||

Welding power | 30KW, Double guns automatic welding | |||||

Number of operators | 1-2 persons, Double guns automatic welding 2-4 persons, Manual welding | |||||

Production efficiency | 8 sections/10h, Refer to the actual site environment | |||||

1, warranty period 1 year from B/L date.

2, within warranty period you could get spare parts for free.

3, You could get free training in our factory.

4, 24 hours technical support by Email, calling or door-to-door service.

We are manufacturer of pile cage welding machine , CNC automatic steel bar bending machine,bending machine ,cutting machine, steel bar straightening machine etc.we also can supply setting up a new factory full line service . We have already exported various kinds of concrete pile ,pole and pipe concern making machines to overseas countries and regions such as Indonesia, Parkistan, Vietnam, Myanmar ,Korea,Malaysia ,South african,Mideast Southeastern Asia, etc..

Team

Our Team

Team

Our Team